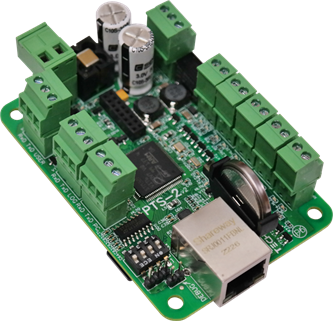

PTS-2 forecourt controller

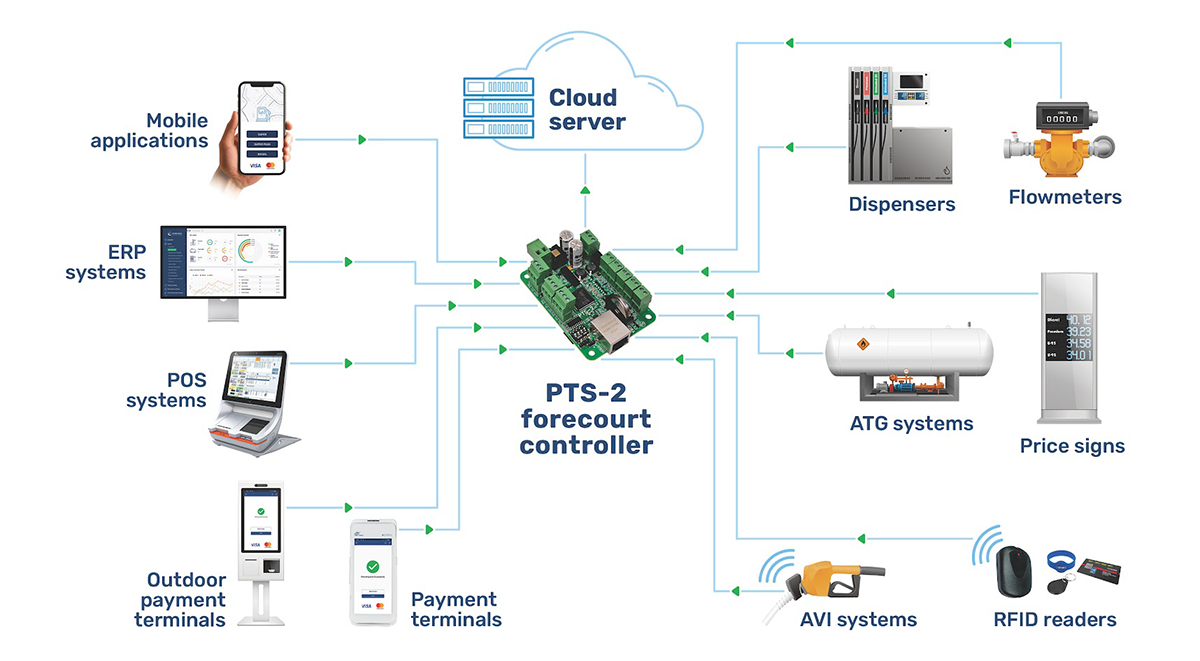

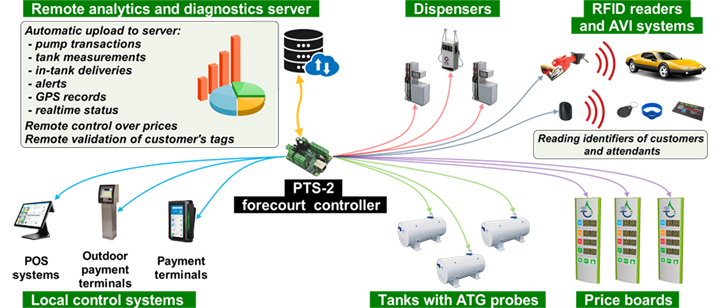

PTS-2 forecourt controller is a powerful modern forecourt controller for provision of control over forecourt equipment of petrol stations, petroleum storage depots and fuel delivery trucks:

- petroleum, LPG and CNG dispensers

- automatic tank gauge systems and probes

- price signs

- RFID tag readers for customers and fuel attendants identification

- AVI systems for vehicles identification

PTS-2 controller supports wireless and wired types of connection to forecourt equipment, making the installations to be simple, fast and reliable.

PTS-2 controller leads internal database for pumps sales, tanks measurements, in-tank deliveries, alerts, GPS records and fuel attendants' and customers' tags. It allows to generate reports using a web browser and also can automatically upload all the registered records to any remote cloud server and to provide a remote control and monitoring over all forecourt equipment installed on petrol stations, petroleum depots and fuel delivery trucks.

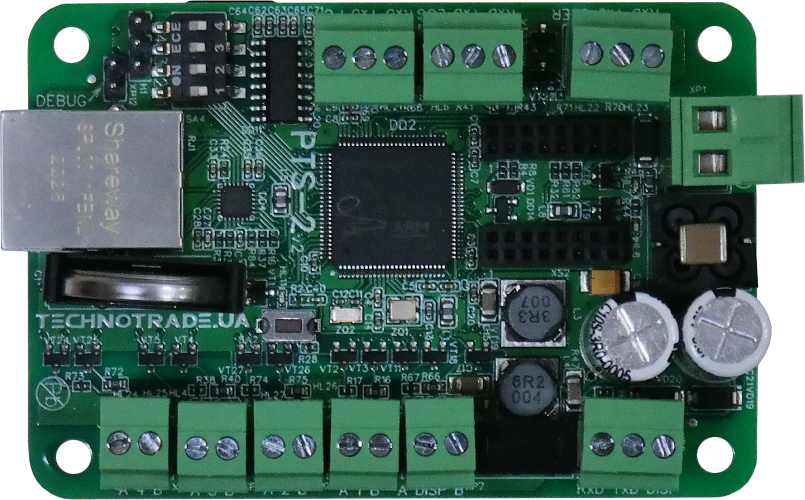

Dimensions of the PTS-2 controller are extremely small with a size of a credit card, which makes its suitable for installation inside any third-party hardware.

PTS-2 controller has a JSON-based easy to implement communication protocol and rich API with open-source applications in C++, C#, Java (for Android), JavaScript programming languages.

Software of the PTS-2 controller has a lifetime license, no regular fees needed.

Downloads

- Introduction

- General application

- Connection to dispensers

- Connection to ATG systems and probes

- Connection to price boards

- Connection to readers

- Connection to automatic vehicles identification systems (AVI systems)

- Wireless communication

- Fuel delivery trucks control and GPS tracking

- Communication to a remote server

- Automatic operation

- Integration with payment systems

- Integration with bank payment terminals

- Tanks automatic calibration

- Conversion between pumps protocols

- Conversion between probes communication protocols

- Monitoring over petrol station activity and alerts

- Fuel dispensers sales data for ATG consoles for tanks reconciliation and autocalibration

- Features and benefits

- Technical characteristics

- Supported pumps and register meters communication protocols

- Supported probes and ATG systems communication protocols

- Supported price boards communication protocols

- Supported readers and AVI systems communication protocols

- Web server

- Configuration of PTS-2 controller video

- Functionality

- PTS-2 controller SDK (Software Development Kit)

- Order information

Introduction #

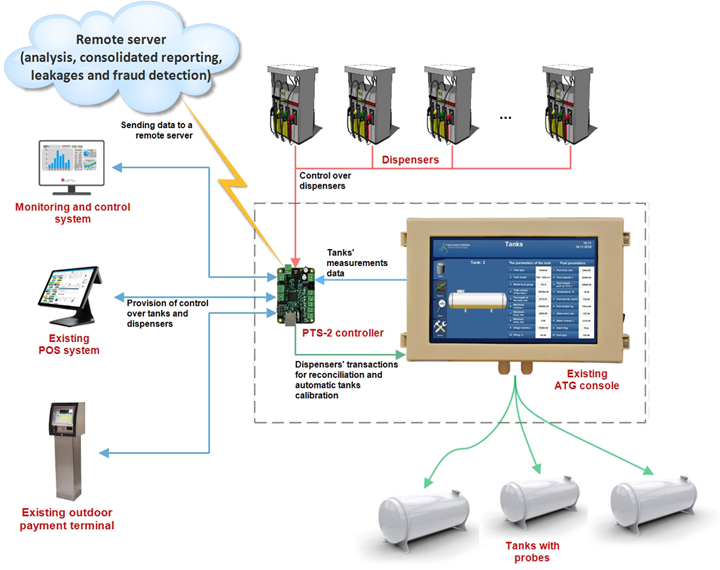

General application #

Using the PTS-2 forecourt controller fuel management systems (POS system, OPT, mobile application, remote server) can provide control over any of the fuel dispensers and monitoring over tanks, control price boards and RFID readers on the forecourt in a common single way and should not matter what are the brands of the equipment installed because the PTS-2 controller undertakes all communication with equipment using its native communication protocols and takes into account all the peculiarities.

This completely simplifies work for a developer of control system: by having implemented communication protocol of the PTS-2 controller you gain ability to provide control over any of dispensers, ATG systems and probes, price boards and readers supported by PTS-2 controller in a common way, so the time required for development of the POS system, cash register, payment terminal or mobile applications is significantly reduced.

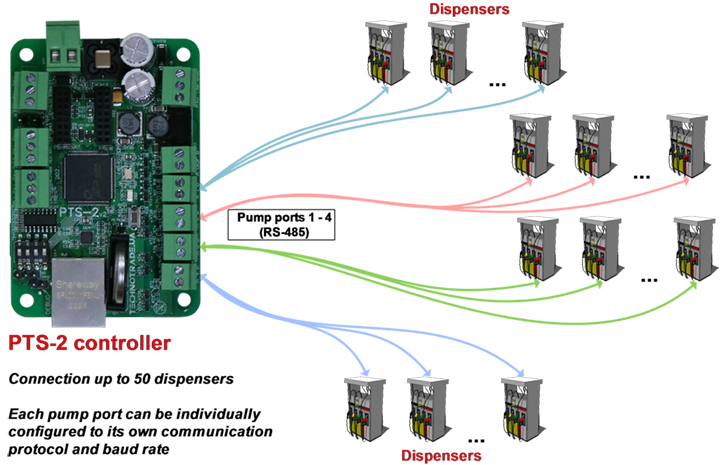

Connection to dispensers #

PTS-2 controller allows to control over up to 120 different fueling places same time, at this connected dispensers can be of 4 various brands, which use different communication protocols.

Following actions can be performed with fuel dispensers regardless the brand of the dispenser used:

- get dispenser status

- start fueling process

- stop fueling process

- suspend fueling process

- resume fueling process

- set/get nozzles’ prices

- get nozzles’ total counters

- get filling information during dispensing process (volume, amount, price)

- get transaction information after dispensing process (volume, amount, price)

- calculation of product temperature-compensated volume in case if there is ATG system or probe installed in tank

- all pumps’ sales data can be recorded in PTS-2 controller for reporting through a web-browser and additionally uploaded to a remote server for processing and analysis.

The PTS-2 controller supports over 135 different brands of fuel dispensers and register meters, here is a list of supported pumps and meters communication protocols.

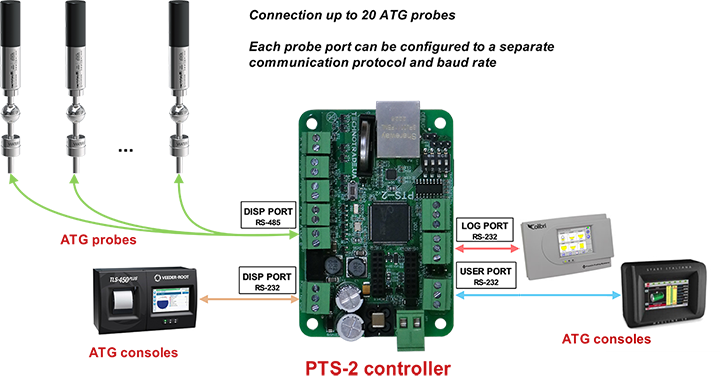

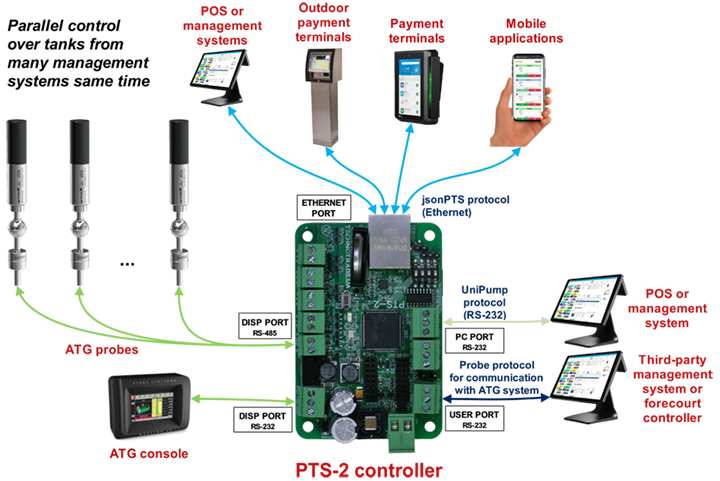

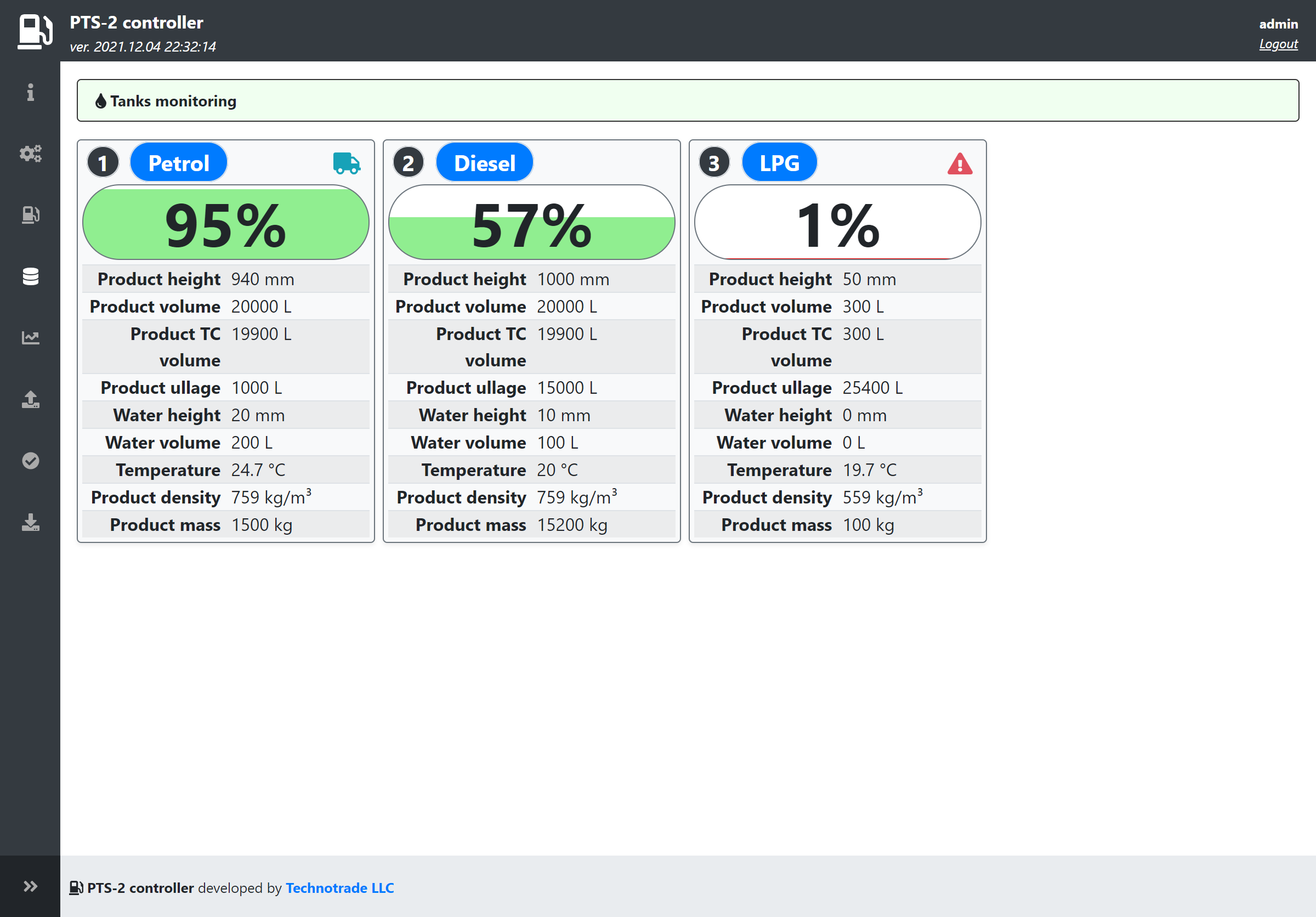

Connection to ATG systems and probes #

PTS-2 controller allows to monitor same time up to 20 tanks, equipped with probes or ATG systems, at this connection of 3 different brands of probes or ATG systems using different communication protocols is possible same time.

Following features are present for any tank regardless of the ATG system or probe used:

- informing probes’ measurements data: product level, water level, temperature, product volume, water volume, product temperature-compensated volume, tank ullage, product density, product mass

- In case if the probes do not provide volume measurements – then PTS-2 controller can provide calculation of product volume based on tank calibration chart and product level, measured by probe

- automatic calculation of product temperature-compensated volume in tank

- automatic detection of product in-tank deliveries received, it can be done even during pumps fueling process

- automatic calculation of product mass

- automatic tank leakage detection

- automatic track of tank alarms: probe failures, high and low product levels, high water level

- at communication to ATG consoles PTS-2 controller can be used for sending fuel dispensers sales data to consoles in order to make console provide tanks reconciliation reports and automatic tanks calibration

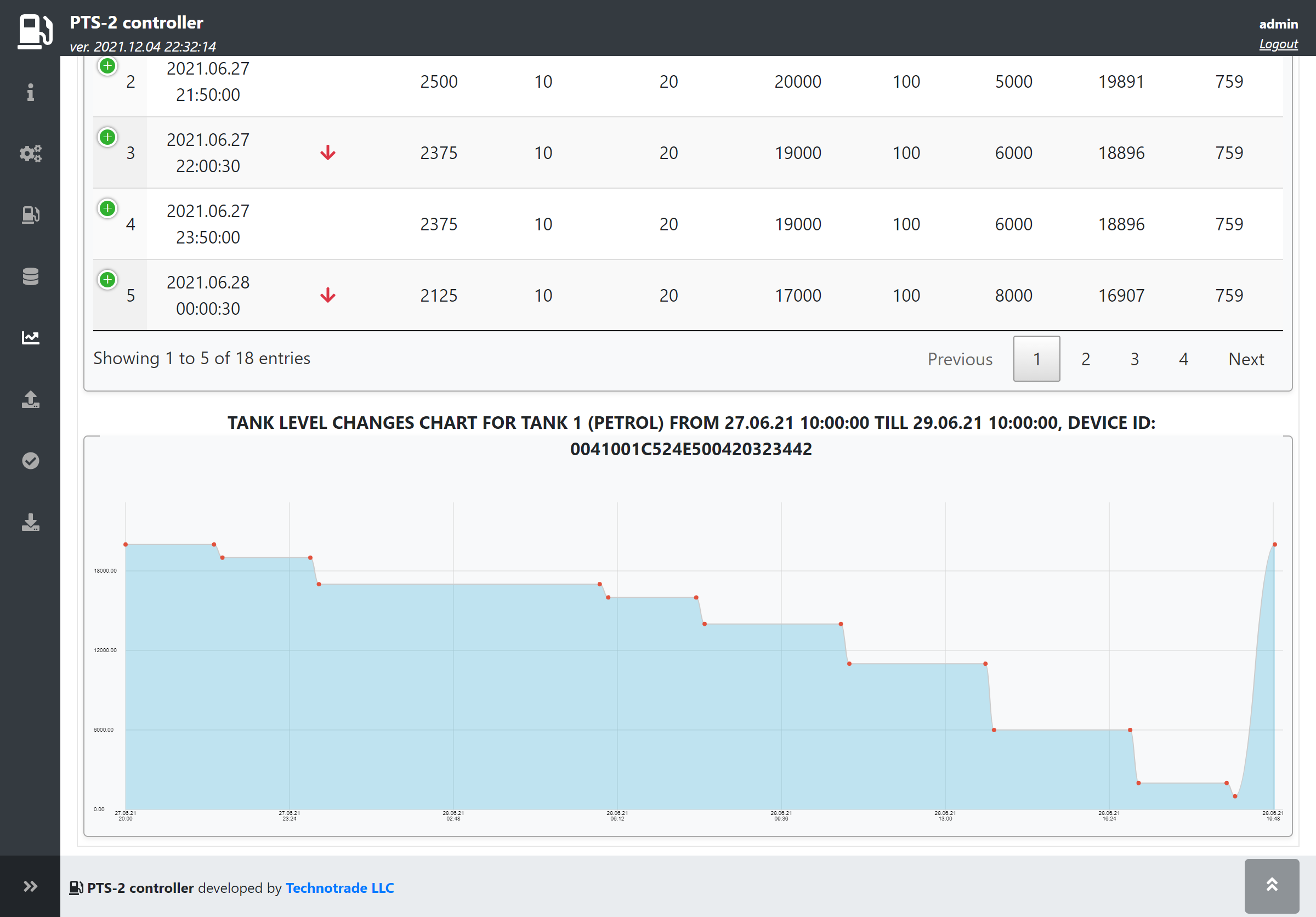

- all tanks’ measurements data can be recorded in PTS-2 controller for reporting through a web-browser and additionally uploaded to a remote server for processing and analysis

The PTS-2 controller supports over 50 different brands of ATG systems and tank probes , here is a list of supported probes and ATG systems communication protocols.

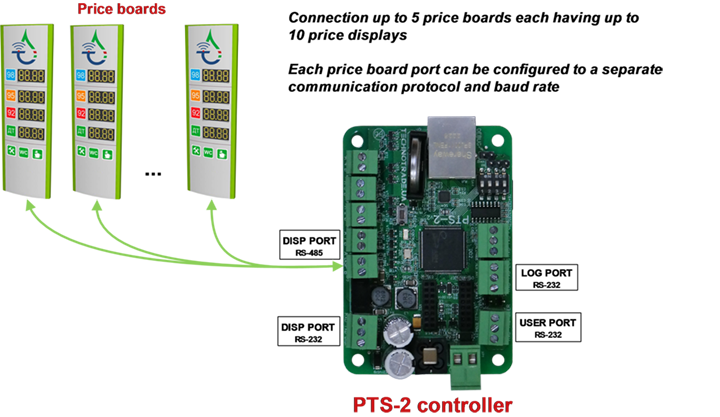

Connection to price boards #

PTS-2 controller allows to control same time up to 5 price boards each having up to 10 price displays, at this connection of 3 different brands of price-boards using different communication protocols is possible same time.

The PTS-2 controller automatically provides control over the price-boards: the prices are automatically updated on the price-boards once they updated in configuration.

The PTS-2 controller supports different brands of price boards and poles, here is a list of supported price boards communication protocols.

If the controller is connected to a remote server - it allows to update the prices in the controller and on the connected price boards realtime from a remote server.

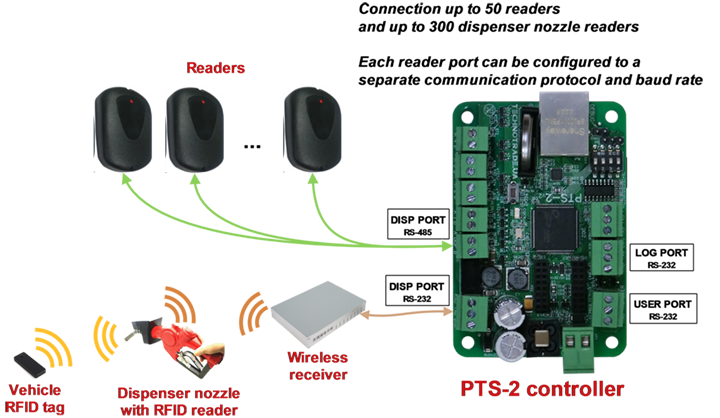

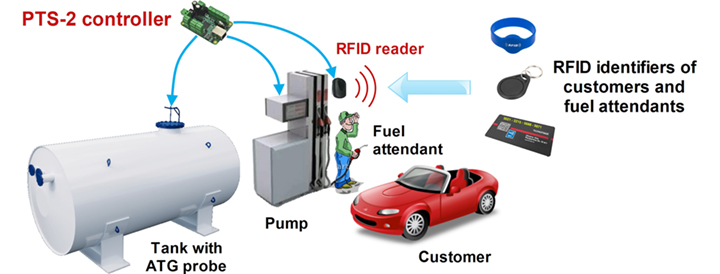

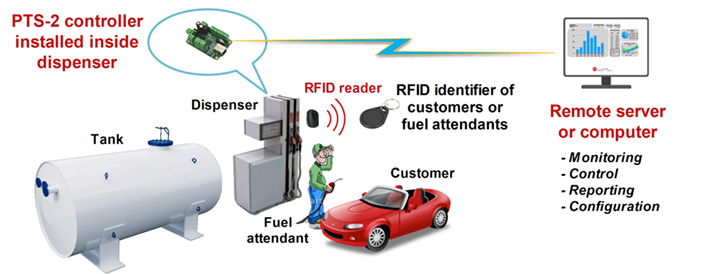

Connection to readers #

PTS-2 controller allows to read the RFID identifiers (cards, tags, wrist straps, etc.) same time from up to 51 readers. The readers can be used as standalone, so as can be linked to pumps programmatically and mounted to pumps (example of the RFID tag to be used on the pump).

PTS-2 controller provides leading a list of tags for customers and fuel attendants, which allows to verify the customer or fuel attendant before the filling to avoid unauthorized fillings.

In the end of the filling the PTS-2 controller saves information on the performed transactions together with the read tags to the database allowing to track actions of the customer or fuel attendant and view in reports sales performed by each customer or fuel attendant.

Providing the fuel attendants with RFID tags allows to solve many important tasks including:

- Fillings can be done only by authorized fuel attendants having valid RFID tags, so it prevents a possibility to fuel by unauthorized users and thus avoid a possibility of stealing the fuel

- All the filling done by fuel attendants are saved in the PTS-2 controller database, the PTS-2 controller allows to generate reports on sales serviced by each fuel attendant, the management of the petrol station can anytime generate a report on how much cash was received by each fuel attendant during any period

- No need to manually write down totals from pumps at start and end of the working shifts - now these values are automatically recorded by the PTS-2 controller and are shown in the generated reports

- No need to fix fuel attendants for certain pumps and fueling places - now any fuel attendant can service any pump filling, the controller provides exact report information on each fuel attendant activity, which allows to save resources

- Management of petrol station can check activity of the fuel attendants and understand who is more active and who is lazy

- Any attempt to cheat or steal the fuel by the fuel attendant is automatically registered by the PTS-2 controller and shown in reports

Connection to automatic vehicles identification systems (AVI systems) #

PTS-2 controller allows to work with different brands of vehicle identification systems (AVI systems), which allow to automatically identify the vehicle once the pump nozzle is inserted inside the vehicle's tank. These systems are used for 3 main purposes:

- to automatically identify the vehicle without interaction of the driver

- to automatically check the account linked to the vehicle (remains of balance, personal loyalty program or discounter, etc)

- to prevent fuel thefts (filling will not start to a different vehicle and a possibility to cheat during the fueling process is eliminated)

Once the pump nozzle is inserted in the vehicle's tank - the management system can automatically know the vehicle's ID and check its account in order to provide it with its personal discount or loyalty policy and start the fueling process, so all is done automatically without the driver's interaction.

During the filling the PTS-2 controller is constantly checking the vehicle tag and in case if the pump nozzle is removed from the vehicle (in order to steal the fuel by filling a canister or some other vehicle) - then the PTS-2 controller automatically pauses the filling, the filling will be automatically resumed once the nozzle is inserted back into the initial vehicle's tank (when the initial tag is detected again).

PTS-2 controller allows flexible configuration for petrol station to state which pump nozzles are equipped with the AVI system and which are not. It allows to install the AVI system only on part of the dispensers (for example those, which are appointed for the fleet customers).

In the end of the filling the PTS-2 controller saves information on the performed transactions together with the detected vehicle tags to its database allowing to track vehicles in reports and to upload the data to a remote server.

PTS-2 controller already supports operation with most popular brands of automatic vehicles identification systems including:

- Hectronic AVI

- HID AVI

- LoopTag AVI

- Mingte AVI

- OTI PetroSmart AVI

- Viotys AVI

- other brands

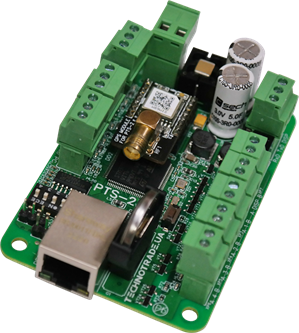

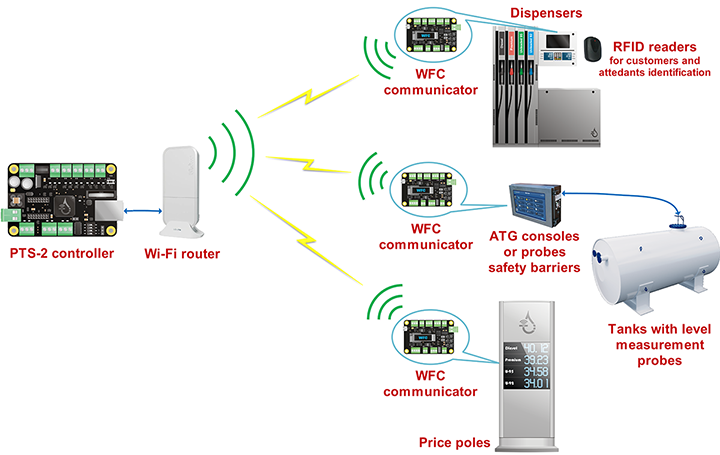

Wireless communication #

The PTS-2 controller can be connected to all forecourt equipment in a wireless way using a WFC wireless forecourt communicator, which allows communication with any brand of dispensers (fuel, LPG, CNG), tank probes and consoles, price poles in a wireless way without a need to put any cables.

WFC communicator has a rich set of electric interfaces on board (various types of current loop interfaces, voltage driven interfaces, RS-485, RS-422, RS-232) suiting to connection of any dispenser brand. WFC communicator has additional port for connection of RFID readers installed on dispensers.

Communication with WFC communicator is done over a secured Wi-Fi network. Configuration of WFC communicator is done using a web browser.

The WFC communicator works in conjunction with the PTS-2 forecourt controller, where the WFC communicator provides wireless communication and connection to devices using various hardware interfaces and the PTS-2 controller manages communication with the connected devices (dispensers, ATG consoles and probes, price poles, readers and AVI systems).

At this you can locate a separate WFC communicator for each of the forecourt devices you need to communicate with. Or you can unite several such devices to use the same single WFC communicator if the used communication interface allows it, for example if these devices are using the RS-485 interface and the same communication protocol.

Dimensions of the WFC communicator board are extremely small with a size of a credit card, which makes its suitable for installation inside any third-party hardware.

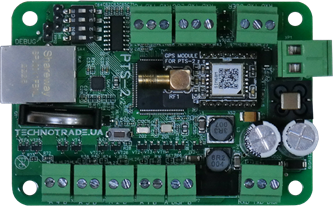

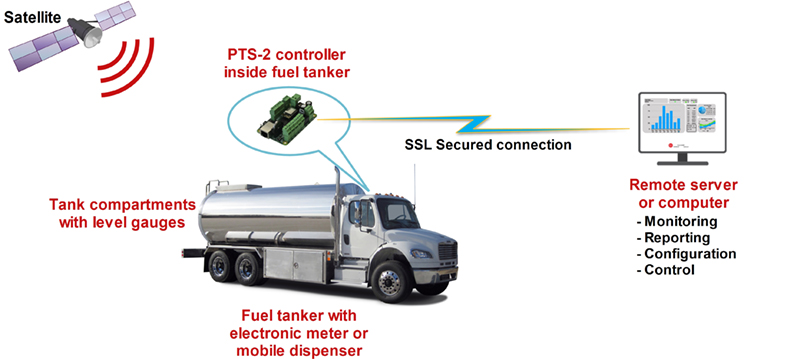

Fuel delivery trucks control and GPS tracking #

PTS-2 controller already supports operation with most popular brands of electronic register meters used on fuel delivery trucks including:

- Gilbarco Veeder Root EMR3 and EMR4

- Total Control Systems TCS 3000

- Liquid Controls LectroCount LCR II, LCR 600, LCR iQ

- Satam Equalis

- SAMPI TEX, TE550

- IPT

- Yokogawa Rotomass

- register meters with pulse output

PTS-2 controller can be equipped with a GPS module for tracking of fuel tankers’ location:

- tracking of the present location

- tracking of the whole route covered for specified period

- tracking of the fuel level in tanks while the fuel tanker was moving on route

- tracking of places, where fuel level in tanks was changed (tank should be equipped with the probe)

- tracking of places, in which fuel was dispensed through the flowmeter

Having this information, it is possible to know present location of the fuel tanker on the route and the, most important, to know possible frauds done with fuel while the tanker is on the route because PTS-2 controller records GPS places if any change of fuel level in tank is done, PTS-2 controller automatically sends this data to a remote server for processing and analysis.

At this, PTS-2 controller automatically accounts all the dispensing performed, with saving to local database and upload to a central server. Additionally, PTS-2 controller can automatically calculate temperature-compensated volume of dispensed fuel if such option is not provided by the meter used.

If the fuel truck has tanks equipped with ATG system – then PTS-2 controller will automatically detect dispensings made from tanks and deliveries made to tanks with saving to local database and upload to a central server.

It is possible to evaluate fuel frauds or leakages done while the tanker is on the route as PTS-2 controller records GPS coordinates and controls any change with fuel levels in tank. Based on these records you can define exact location, where fuel removals or receptions happened without allowed registration.

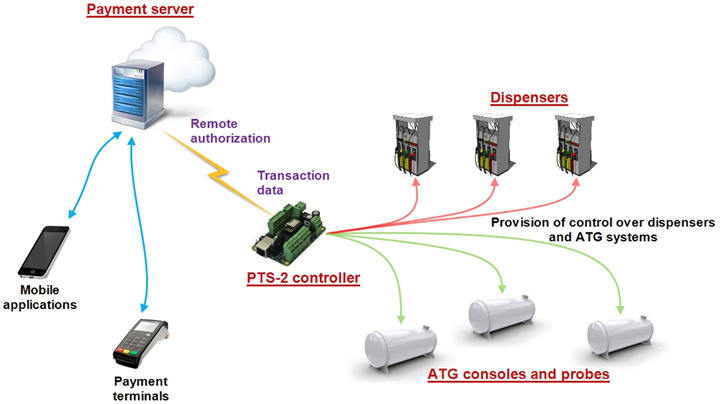

Communication to a remote server #

Being installed on petrol stations without static IP-addresses or in the mobile fuel delivery truck sometimes there is a task to communicate to a remote server to gather information for reporting, to receive some updates in configuration or even for remote control from a server. For such tasks the PTS-2 controller can itself establish connection to a remote server by server's IP-address or domain name.

PTS-2 controller is able to constantly communicate with remote server without a need to have its own static IP-address for upload of data to the remote server online for reporting and analysis. PTS-2 controller can connect to a remote server itself and send all the data in JSON format, which is convenient for processing, so any third-party servers can easily implement support of PTS-2 controller to work with its data. The remote server at this can send any requests to the PTS-2 controller, for example to authorize the pump, to update fuel grades prices or to update a list of allowed fuel attendants tags.

Also, PTS-2 controller can establish constant connection to a remote server using the WebSocket protocol (according to RFC 6455) with a purpose to allow the server to execute any requests it needs like setting/getting configuration, provision of control over pumps and tanks, getting reports, etc. This application is important when a remote server should completely control the PTS-2 controller.

In both cases the PTS-2 controller connects to a remote server as a client, so there is no need to have any static IP-address on the place of PTS-2 controller installation.

The PTS-2 controller allows to upload the following information to a remote server:

- Information on each performed pump transaction:

- pump sale start date and time

- pump sale end date and time

- pump number

- nozzle number

- fuel grade ID

- fuel grade name

- tank number, to which the pump nozzle is linked

- transaction number

- pump price

- dispensed volume

- dispensed temperature-compensated volume (volume converted to 15 degrees Celsius)

- dispensed money amount

- value of volume counter in pump on the transaction end

- value of money amount totalizer counter in pump on the transaction end

- value of customer or fuel attendant tag applied for the transaction (the fuel attendant ID card to authorize the pump or the customer's discount/loyalty card)

- ID of a management system authorizing a pump (local POS system or OPT)

Having this data the remote server is able to:

- generate reports with all details on each pump sales done

- calculate the flow speed of each pump nozzle

- check if there were stealings of fuel done through authorized sales without the controller control (by the pump totalizers counters, which are non-erasable and non-resettable and are incremented regardless the transaction is done in manual mode or automatically, so in case if the totalizers counters were incremented more than a sale done - then someone was doing a filling when a pump is in manual mode, which might be a theft)

- decide which pump is more attractive and more productive

- others

- Information on the customer's tag brought to the pump reader before the filling:

- tag identifier

- pump number selected

- nozzle number selected

- fuel grade ID selected

- fuel grade name selected

- price of selected fuel grade

Having this data the remote server provides the following actions:

- validates whether the tag is valid and can be used for filling

- validates whether the customer is allowed to fill selected fuel grade

- validates whether the customer is allowed to fill on this petrol station

- validates customer's account type: money amount, volume, discount or any other

- validates customer's account balance remains (in case of prepaid/credit money or fuel volume wallets)

- validates the price of selected fuel grade and whether the customer has any special price due to discount, loyalty policy, happy hours, other reasons

- validates customer's details for local verification of the customer on site (if is it needed): name, phone, vehicle number, registration number, company name, any others

Having processed the request, the loyalty system server responds back to the PTS-2 controller.

If the customer's tag is valid and its account has sufficient remains on its balance - then the PTS-2 controller automatically authorizes the pump for the value of balance remains stored on customer's account (volume or money amount depending on the customer's account type) and takes into account the possible customer's special price. After the filling is finished - then the PTS-2 controller immediately uploads details on the performed pump transaction using customer's tag to the fuel loyalty system server, so that it could write off the values of dispensed volume and money amount during the filling from the customer's account.

- Information on each registered tank measurement (the PTS-2 controller uploads the tank measurements data to a remote server each time it detects a change in the product height):

- date and time of measurement

- tank number

- probe error

- alarms present (products height low or high, water height high)

- product height value

- water height value

- product temperature value

- product volume value

- water volume value

- tank ullage volume value

- product temperature-compensated volume value

- product density value

- product mass value

- detected tank alarms and leakage

Having this data the remote server is able to:

- have online data for each tank

- have statistics for each tank usage with a possibility to make forecasting for future needs

- if combined with data on pumps sales from the tank the remote server is able to generate reports on reconciliation meaning to see how much fuel has to be stored in the tank on some moment and how much is actually stored there and thus to understand if there is a possible leakage or thefts from the tank.

- others

- Information on each registered in-tank delivery (the PTS-2 controller itself monitors tanks for in-tank deliveries, saves them to database and uploads to a server):

- date and time of in-tank delivery start

- date and time of in-tank delivery end

- tank number

- product height value on in-tank delivery start

- product height value on in-tank delivery end

- water height value on in-tank delivery start

- water height value on in-tank delivery end

- product temperature value on in-tank delivery start

- product temperature value on in-tank delivery end

- product volume value on in-tank delivery start

- product volume value on in-tank delivery end

- product temperature-compensated volume value on in-tank delivery start

- product temperature-compensated volume value on in-tank delivery end

- product density value on in-tank delivery start

- product density value on in-tank delivery end

- product mass value on in-tank delivery start

- product mass value on in-tank delivery end

Having this data the remote server is able to understand how much fuel was received in each tank.

- Found errors and alarms:

- detected pumps offline status

- detected pumps errors

- detected probes offline status

- detected probes errors

- detected tanks alerts (critical high product height, high product height, low product height, critical low product height, high water height)

- detected tanks leakages

- detected tanks probes floats stuck

- detected price-boards offline status

- detected price-boards errors

- detected readers offline status

- detected readers errors

- operation time of the controller

- detected absence of power supply

- low battery voltage

- high CPU temperature

- others

Having this data the remote server can instantly alarm technical personnel about the found problems to quickly solve them and thus keep the petrol stations work stable and safe.

- GPS tracking records (in case if the PTS-2 controller is installed inside a fuel delivery truck):

- date and time of GPS record

- fuel track latitude value with North/South indicator

- fuel track longitude value with East/West indicator

- fuel track speed over ground

- fuel track course over ground

Having this data the remote server can display location of the fuel track on the map with indication what is its speed and height over ground. Also, it can know in which places the fuel delivery truck made fillings and also product level changes in tank were detected (as a mean to define possible stealings of fuel along the fuel delivery truck movement).

- Online realtime status of each pump (meter), tank probe, GPS receiver, alerts and the PTS-2 controller: having this information the remote server is able to know everything happening realtime on the site. Data is sent each second or faster, the server software can use its own algorithms for calculation of various indicators as it was connected to the forecourt equipment itself locally.

- PTS-2 controller configuration: the remote server is able to remotely receive configuration from the PTS-2 controller and also to update the configuration in the PTS-2 controller. As an example the remote server having sent the fuel grades prices update request to the PTS-2 controllers will automatically update of prices on the pumps and in the price boards on the whole network of petrol stations.

The remote server anytime can request the PTS-2 controller to perform any request or change in configuration, for example:

- update prices for fuel grades

- update a list of allowed fuel attendants tags

- authorize a pump

- stop all the pumps in case of some emergency

- get tank measurements data

- get reports information

- any other

Automatic operation #

This feature allows PTS-2 controller to work standalone on the station without any additional control system, providing control over pumps and tanks, saving all data to the database and uploading to a remote server automatically. This feature allows to have completely automatic installations with minimal hardware used on the site. PTS-2 controller guarantees stable application during a long period.

At this PTS-2 controller automatically authorizes pumps and stores all sales to database. Also, PTS-2 controller tracks all changes of product measurements inside tanks with storing of all changes in database and automatic registration of in-tank deliveries and discharges from tanks.

Fuel attendants are equipped with RFID tags used for authorization of fuel dispensers, which allows to avoid unauthorized fillings and to track of which pump sales are done by which fuel attendant.

All database records are automatically uploaded to remote server for subsequent analysis: reconciliation, automatic tanks calibration, detection of leakages and thefts.

PTS-2 controller can be used as IoT device for communication with dispensers and ATG probes, collecting and storing data and uploading to a remote server using encrypted communication.

Integration with payment systems #

PTS-2 controller has rich API for developers and can be easily integrated with payment software systems, retail POS systems and ERP software. PTS-2 controller pushes information on each performed transaction to remote server, so server can get all data on sales immediately from PTS-2 controller.

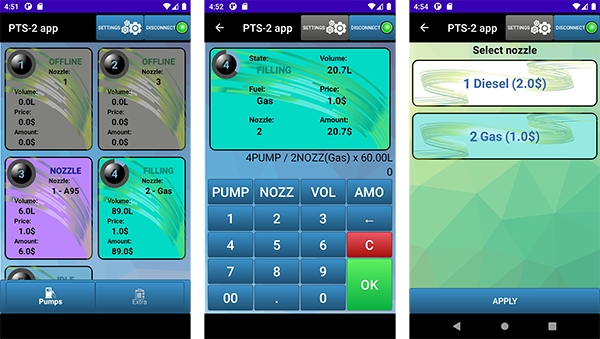

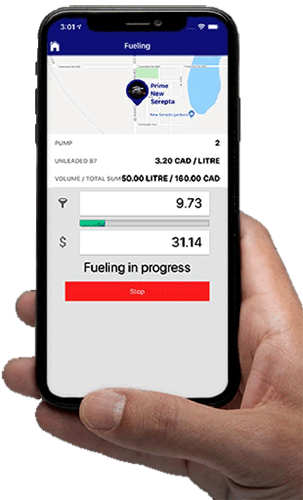

Operation with the PTS-2 controller is already integrated in a number of popular payment systems and applications. The customers can use their mobile phones and devices for payment for the ordered fuel online using the bank cards and also to gain their personal loyalty points and discounts.

The customer application can work in parallel with the local management system installed at day time and also for the self-service during the night time when the POS system is switched off and there is no cashier. The mobile applications allows the customer to select the close petrol station and make the payment in a convenient way with keeping of control over the filling process.

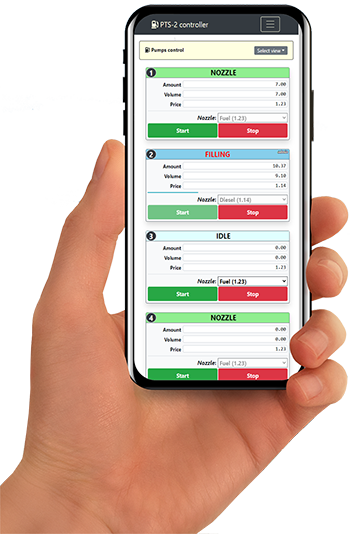

|

|

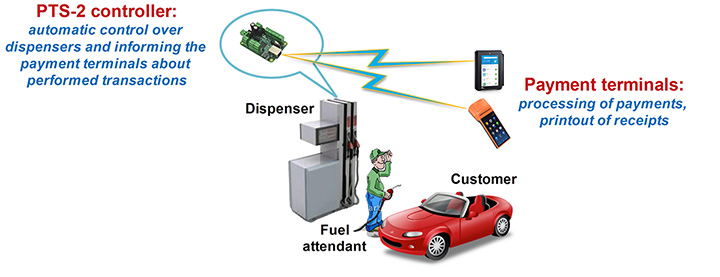

Integration with bank payment terminals #

PTS-2 controller can be used together with bank payment terminals mounted inside the pumps or handheld terminals brought by the fuel attendants.

The payment terminal application is to process the customer’s bank card and give a command to the PTS-2 controller for starting a filling with required order limit, the PTS-2 controller is to perform the filling and stop on the ordered dose with informing the payment terminal on the performed transaction details, payment terminal is to withdraw the cost of fuel dispensed from the customer’s account and to print a customer’s receipt.

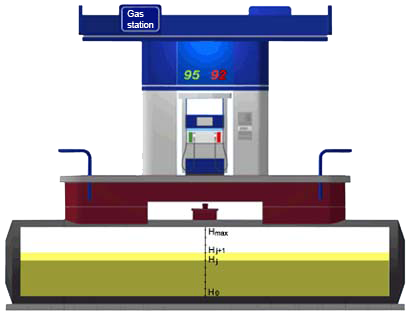

Tanks automatic calibration #

At petrol stations horizontal cylindrical steel tanks are used to store petroleum products. The tank is a measuring instrument that has a calibration table compiled during its manufacture process. The calibration chart is a document, which stores correspondence between the fuel height in tank and its volume. The tank calibration chart is used for calculation of the fuel volume remains in tanks, in-tank deliveries registration, temperature-compensated volume calculation, others.

During operation tanks tend to change their parameters due to various types of deformations and external influences: this may be deformation of the body of the tank, tank tilt, foreign objects entering the tank, etc. Therefore, during operation of the tank the initial calibration chart of the tank becomes more and more different from its real calibration chart. The discrepancy between the actual calibration chart and the initial chart, which was provided from the factory at tank supply, leads to the loss of real accounting of the movement of petroleum products at petrol stations. It leads to a necessity to provide periodically tank recalibration in order to prepare a new actual calibration chart, which corresponds to present tank state.

Classical method of tank recalibration includes emptying of the tank from fuel and then a special procedure of filling/unfilling the fuel with water. This procedure is quite costy because it requires a special equipment and also you need to stop the operations with the tank, which leads to stopping of the petrol station operation.

In order to make this procedure to be simple and to keep your tanks to have the actual calibration chart without a need to stop the petrol station operation Technotrade company added the tanks automatic calibration procedure directly in the PTS-2 forecourt controller.

The PTS-2 forecourt controller is able to perform tanks automatic calibration automatically without stopping the petrol station operation. The process is fully automated and each tank’s calibration chart is automatically calculated and adjusted in the process of the tank operations. For this process the PTS-2 controller communicates to both the pumps and the ATG probes installed inside the tanks. In the result of this process the PTS-2 controller forms and constantly adjusts the accurate calibration charts for each of the tanks, which suit to their actual state and which are used for precise calculation of the fuel volume remains in tanks, in-tank deliveries registration, temperature-compensated volume calculation and other technological processes.

Calculation and formation of tank calibration charts is performed automatically during the system operation using results of measurement, received from the ATG probes installed inside the tanks and from the fuel dispensers, which fill the fuel. The system does not need any stoppage of the petrol station operation. The PTS-2 controller supports more than 200 brands of dispensers and ATG probes from various manufacturers.

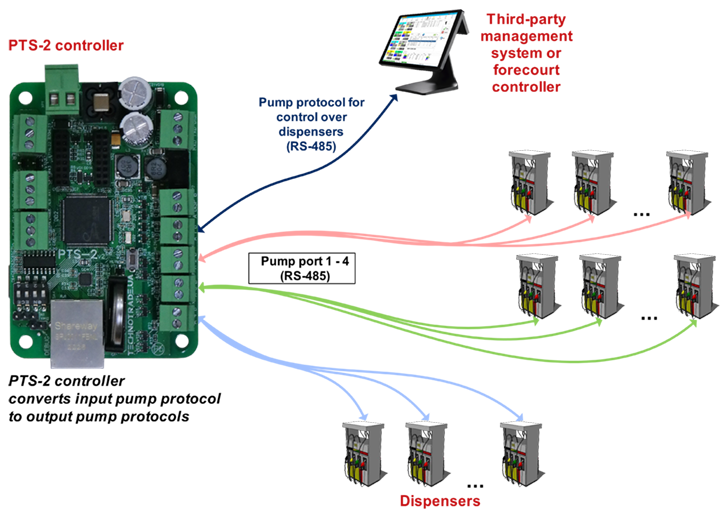

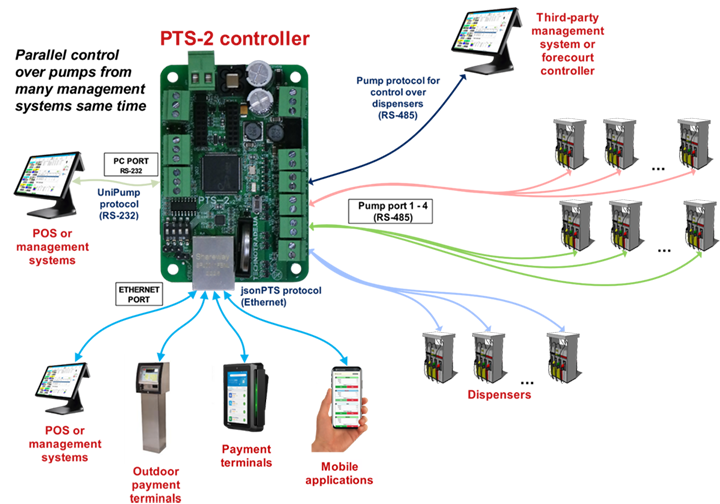

Conversion between pumps protocols #

PTS-2 controller can work as a protocols converter converting between fuel dispensers’ communication protocols and also between ATG systems’ and probes’ communication protocols.

In case if the POS system already knows some open communication protocol of dispensers then it can use PTS-2 controller for its conversion to any other pump protocols without any additional integration.

Control over dispensers can be done in parallel from many management systems connected through pump ports, PC port and Ethernet port in the PTS-2 controller. The PTS-2 controller internally tracks which control system locks control over dispensers.

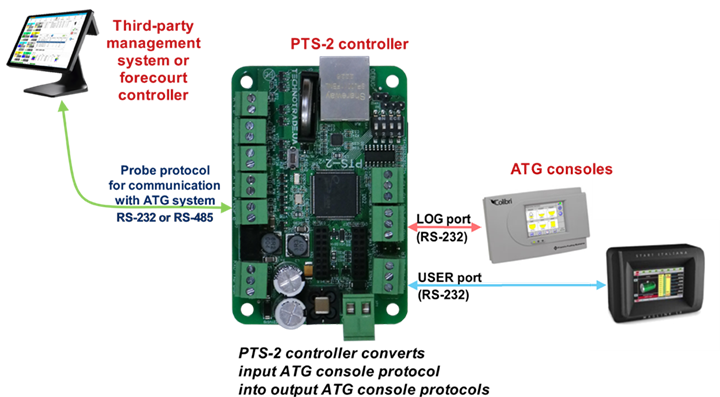

Conversion between probes communication protocols #

PTS-2 controller can work as a protocols converter converting between fuel dispensers’ communication protocols and also between ATG systems’ and probes’ communication protocols.

In case if the POS system already knows some open communication protocols of ATG consoles then it can use PTS-2 controller for its conversion to any other ATG console or probe protocols without any additional integration.

Control over tanks can be done in parallel from many management systems connected through probe ports, PC port and Ethernet port in the PTS-2 controller.

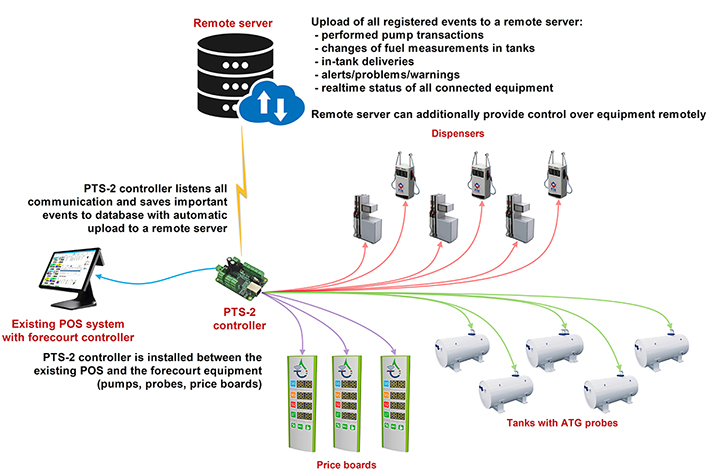

Monitoring over petrol station activity and alerts #

While working on the station (being connected to management systems or standalone), the PTS-2 controller is able to monitor everything happening on the station, save it and upload to the customer's remote server for remote control, reporting, analysis, instant technical support and maintenance.

The PTS-2 controller will pass through all communication with saving of all important events to its database with automatic upload to a remote server:

- performed pump transactions

- changes of fuel measurements in tanks

- performed in-tank deliveries

- found alerts and errors in connected equipment

- realtime status of all connected equipment

- GPS records of the route (if installed inside fuel delivery trucks)

All this data is automatically collected and immediately uploaded to a remote server for reporting and analysis.

Fuel dispensers sales data for ATG consoles for tanks reconciliation and autocalibration #

Possibilities of the PTS-2 controller allow to apply it in various ways for provision of control over forecourt equipment at petrol stations and allow its easy integration with existing POS systems and OPT terminals at petrol stations.

One of the applications is listening of communication exchange between POS system and dispensers and sending of dispensers’ transactions to the ATG console for provision of tanks reconciliation and automatic calibration. Most of the petrol stations with installed ATG consoles do not have this option due to POS system can not provide sending of dispensers’ transactions to the console. Installation of the PTS-2 controller between POS system and dispensers solves this problem and without any additional integration from the side of POS system.

Additionally, it is possible to apply PTS-2 controller inside the casing of the ATG console. At this a scheme of connection specified on the above image is saved, but at some extra development of the console GUI it is possible to make a completely new function of the console – provision of monitoring and control over dispensers from the console in parallel with POS system. As a result, the console becomes a common system of control, monitoring and account providing:

- connection of console to any POS system, OPT terminal for provision of control over dispensers

- possibility to connect various brands of probes, which communication protocols are not supported by the console

- transmission from PTS-2 controller to console data on sales transaction of dispensers for formation of reconciliation reports and automatic tanks calibration

- additional possibility to monitor and control fuel dispenser operation from the console display in parallel to POS system already installed at petrol station (needs update of console software)

Features and benefits #

- Credit card size for easy installation in any hardware

- Supports more than 140 different brands of dispensers

- Supports more than 50 different brands of ATG systems and probes

- Supports simultaneous operation with 120 dispensers, 20 tanks probes, 120 readers, 5 price boards

- Wired or wireless connection to forecourt equipment

- SSL/TLS layers for secured communication as a web-server and as a web-client

- Built-in web-server for monitoring, configuration, reporting and control

- Leading of customers and fuel attendants tags for elimination of unauthorized sales and provision of detailed reporting

- Communication interfaces with control systems: RS-232, RS-485 and Ethernet

- Rich set of interface converters

- Able to work automatically standalone without POS (saving of data to local database for reporting), can be controlled by POS or can work in parallel with existing POS

- Automatic communication to a remote central server

- quick informing a remote server about any alerts or errors happening on the forecourt, which allows to quickly react and provide the quickest solution with minimum downtime of the site

- Conversion between pumps protocols and between ATG probes protocols

- C# API (NET Core) library and an open-source application compatible with various operating systems (Windows, Linux, MacOS) with different processor architectures

- C++ API

- Java API for Android

- JavaScript API

- GPS module for tracking the route of the fuel delivery trucks and places of filling/unfilling of petroleum from their tanks

- Cost effective

Technical characteristics #

| PARAMETER | VALUE |

|---|---|

| Power supply voltage | 12 V DC |

| Current consumption | 700 mA max |

| Temperature range | from -40°C to +60°C |

| Weight | 200 g |

| Overall dimensions | 85 x 58 x 30 mm |

| Connection to pumps (fuel, diesel, CNG, LPG) and register meters | |

| Maximal number of pumps connected | Up to 120 |

| Total number of pumps brands supported | 150 |

| Connection to ATG systems/consoles and probes/gauges | |

| Maximal number of ATG consoles and probes connected | Up to 20 |

| Total number of ATG consoles and probes brands supported | 50 |

| Connection to price boards | |

| Maximal number of price boards connected | Up to 5 |

| Connection to RFID/UHF readers | |

| Connection to automatic vehicle identification (AVI) systems | |

| Maximal number of readers connected | Up to 700 |

| Communication with management systems over Ethernet interface | |

| Communication with management systems over RS-485 interface | |

| Communication with management systems over RS-232 interface | |

| Encryption of communication with the management systems | |

| Number of simultaneously connected management systems | No limitation |

| Support of communication with management systems using WebSocket protocol | |

| Presence of internal database for performed pump transactions, tank measurements, in-tank deliveries, alerts, GPS records | |

| Automatic mode of control over pumps | |

| Price scheduler | |

| Presence of a built-in web-server for configuration, management, monitoring, reporting and diagnostics | |

| Users and roles management and authentication | |

| Conversion between pumps protocols | |

| Conversion between probes protocols | |

| Conversion between price boards protocols | |

| Automatic calculation of temperature-compensated volume | |

| Automatic calculation of in-tank deliveries to tanks | |

| Automatic tanks calibration | |

| Automatic leakage detection from tanks | |

| Support of GPS module for vehicles geolocation, reporting on travelled route and places of pumps fillings and changes of product levels in tanks | |

| Integration with payment solutions | |

| Integration with bank payment terminals | |

| Collection of forecourt diagnostics information for online technical support (alerts, errors, warnings) | |

| Leading internal database of tags (for fuel attendants and customers) | |

| Offline operation | |

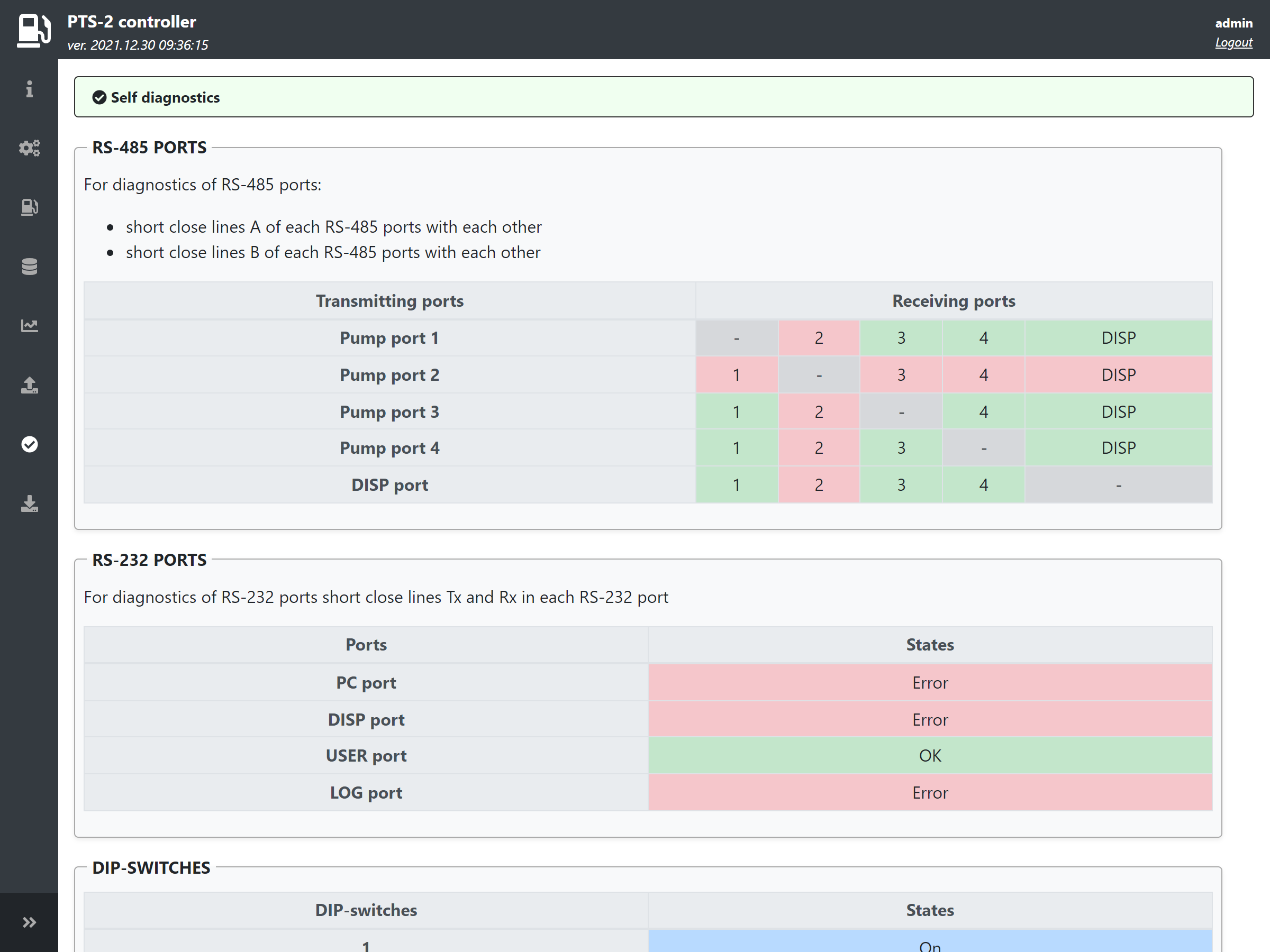

| Built-in self-diagnostics | |

| Realtime communication to a remote server | |

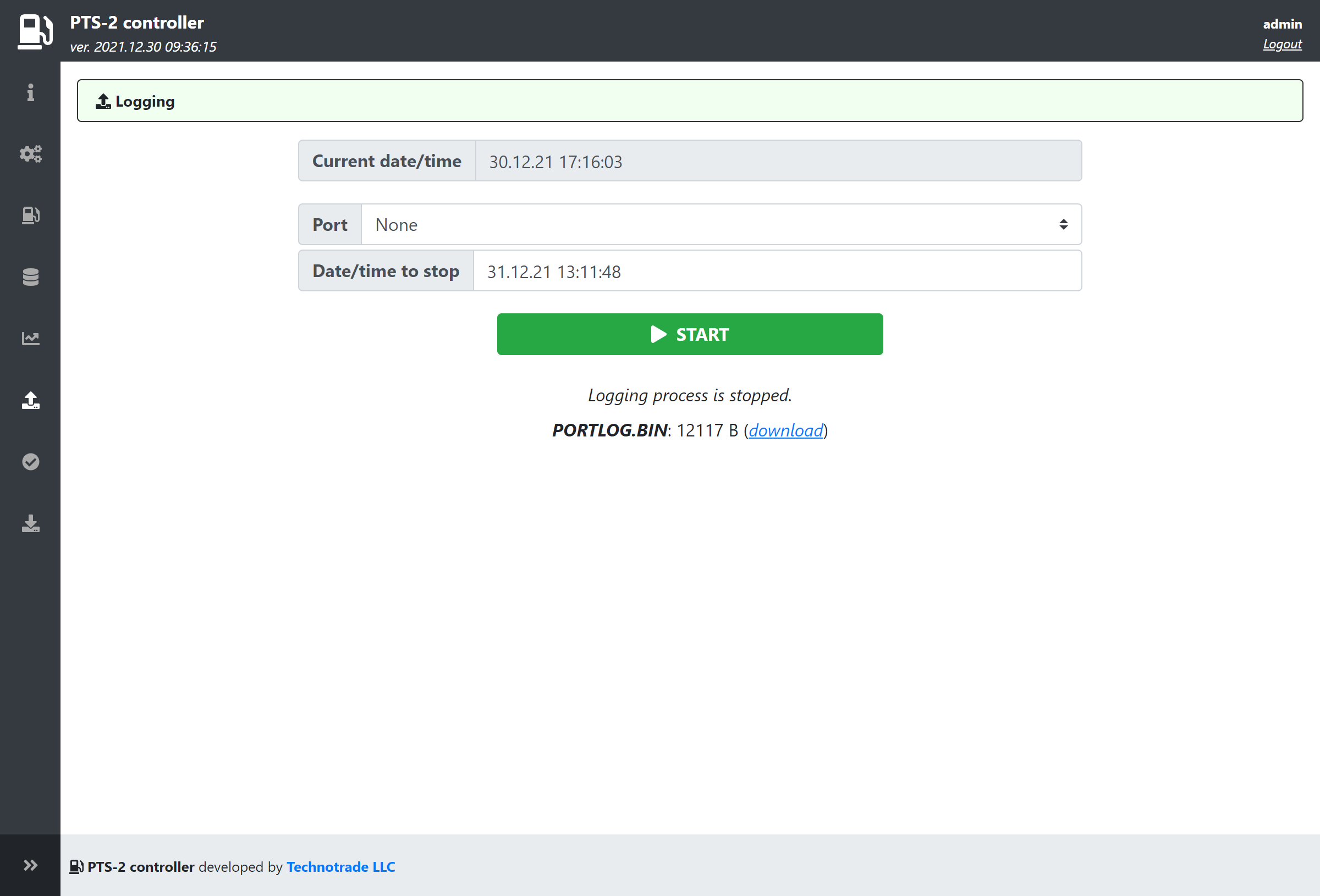

| Logging of operation | |

| Remote firmware update | |

| Software Development Kit (SDK) for developers | |

| Presence of API for quick integration into third-party solutions |

Supported pumps and register meters communication protocols #

Need more protocols?

We are constantly expanding a list of supported communication protocols and forecourt equipment.

Please contact us if you are interested in other pumps or probes brands, communication protocols or control equipment not listed here.

Supported probes and ATG systems communication protocols #

Need more protocols?

We are constantly expanding a list of supported communication protocols and forecourt equipment.

Please contact us if you are interested in other pumps or probes brands, communication protocols or control equipment not listed here.

Supported price boards communication protocols #

Need more protocols?

We are constantly expanding a list of supported communication protocols and forecourt equipment.

Please contact us if you are interested in other pumps or probes brands, communication protocols or control equipment not listed here.

Supported readers and AVI systems communication protocols #

Need more protocols?

We are constantly expanding a list of supported communication protocols and forecourt equipment.

Please contact us if you are interested in other pumps or probes brands, communication protocols or control equipment not listed here.

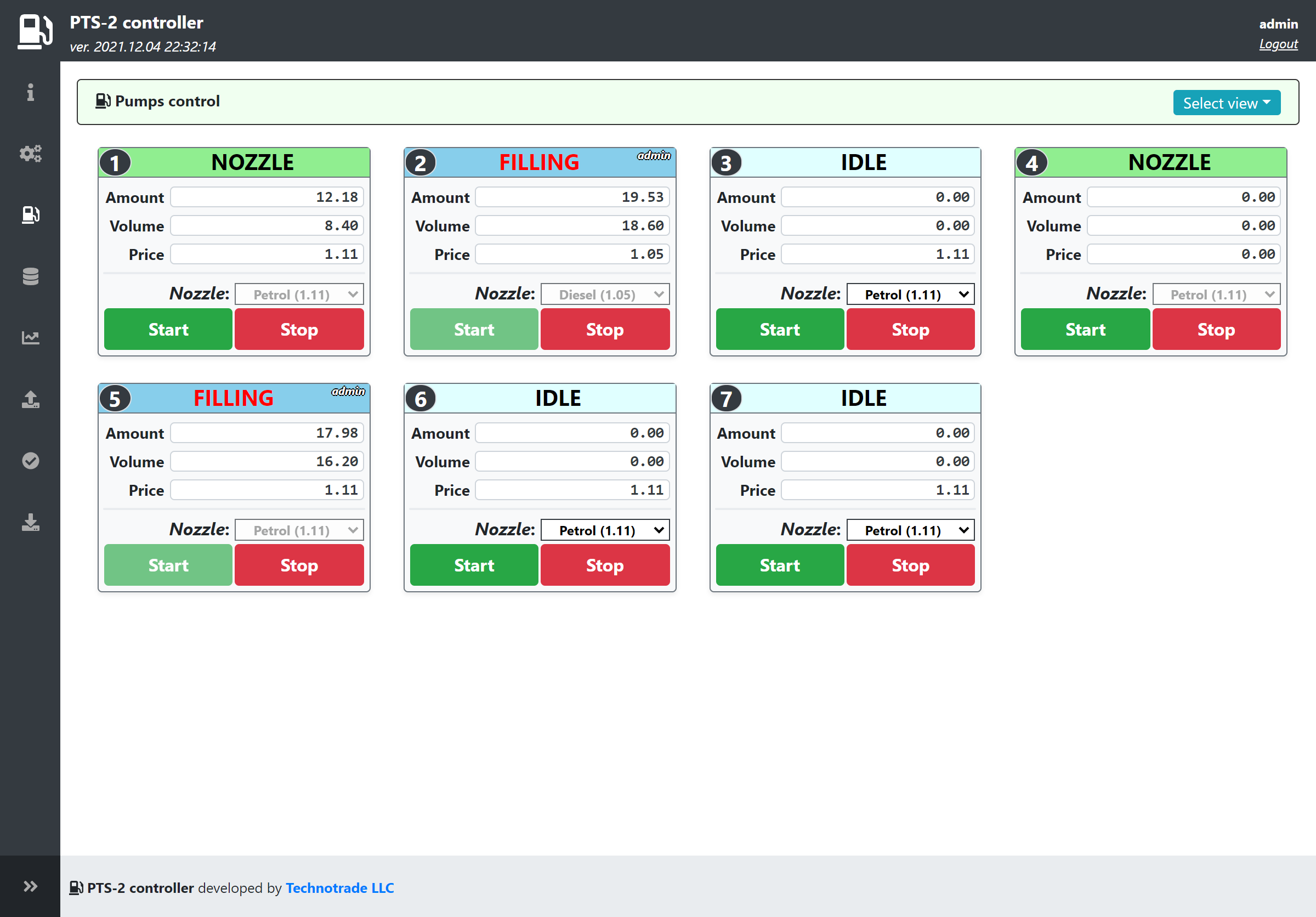

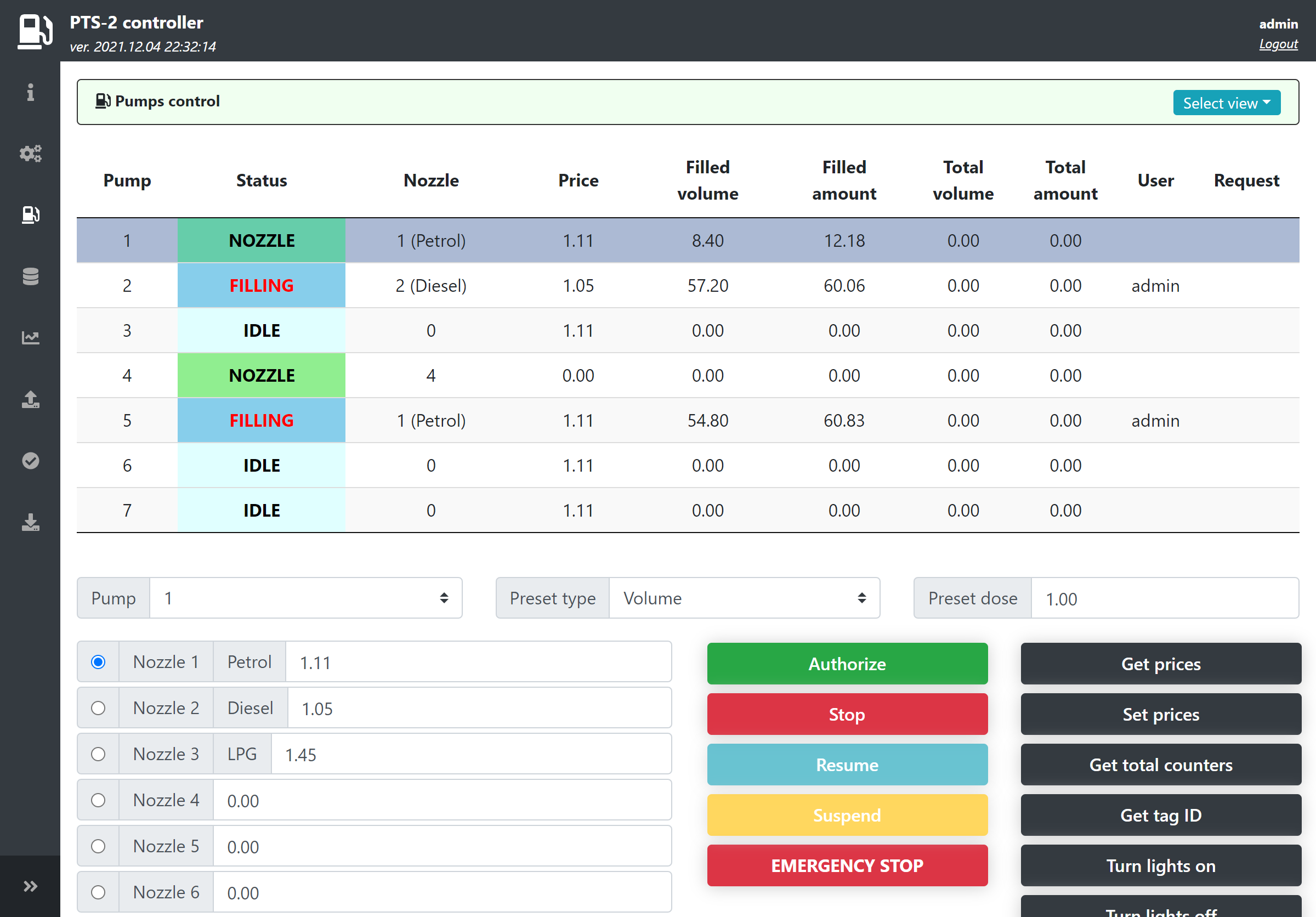

Web server #

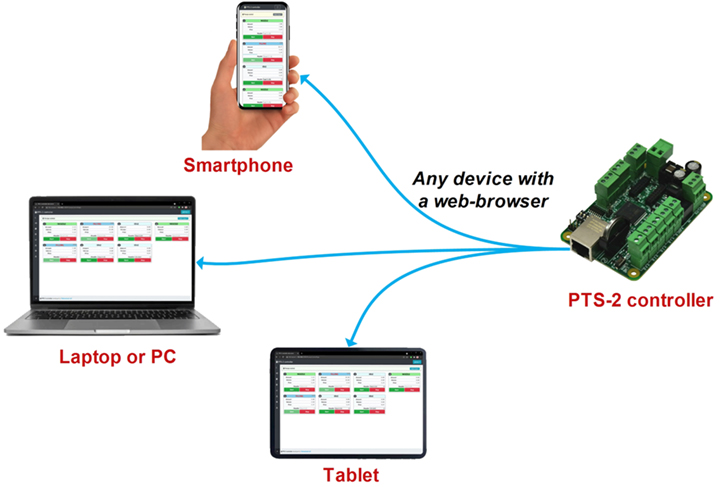

PTS-2 controller has a built-in web-server, which allows to communicate with it as locally, so as remotely using HTTP or HTTPS protocols.

Web-server allows to make full control of PTS-2 controller including control over pumps, monitoring over tanks, reporting, configuration, diagnostics, firmware update, others. A web-server has a responsive modern graphical user interface, so computers, tablets, mobile devices or any other devices with a web browser can connect to PTS-2 controller and display its web server pages in a convenient way.

Communication with the web-server is done using HTTP POST requests with data formatted in JSON format, so implementation of this protocol should be easy for any third-party system.

Web-server has adoptive interface and was developed to suit to various types of mobile devices: PCs, laptops, tablets, smartphones.

Configuration of PTS-2 controller video #

Functionality #

- Supports over 125 communication protocols of fuel dispensers, ATG systems, price boards, readers and AVI systems. List of supported communication protocols is constantly growing. Single firmware of PTS-2 controller contains all available communication protocols for fuel dispensers and ATG systems.

- Control up to 120 fuel dispenser sides (fueling places): PTS-2 controller has 4 independent pump ports, each of them can be configured to its own communication protocol and baud rate, thus PTS-2 controller provides communication with connected dispensers simultaneously using up to 4 various communication protocols.

- Control up to 20 ATG probes (gauges): PTS-2 controller has 3 independent probe ports, each of them can be configured to its own communication protocol and baud rate, thus PTS-2 controller provides communication with connected probes simultaneously using up to 3 various communication protocols.

- Control up to 5 price boards: each price board can have up to 10 price displays.

- Control up to 120 pump readers: readers can be assigned to specific pump sides or can be configured to serve any pump side.

- Support of customers and fuel attendants tags, which can be used for automatic verification of the customer or fuel attendant before the dispensing by pump and also for leading account of al the sales performed by the customer or fuel attendant with generation of detailed and summary reports.

- Unified approach to management over any forecourt equipment: using PTS-2 controller control over any supported fuel dispenser or ATG system is done in exactly the same way by the management system (POS system, cash register, OPT terminal, server or mobile application, etc). PTS-2 controller has a single common communication protocol. Thus having once implemented the protocol into the management system (or its API) the management system will be able to provide control over any of the supported fuel dispensers and ATG systems in exactly the same way.

- Automatic mode of operation: PTS-2 controller automatically authorizes dispensers and saves all pumps sales and tanks measurements to SD flash disk with a possibility of reports generation.

- Automatic calculation of product volume in tank based on tank's calibration chart.

- Automatic calculation of product temperature-compensated volume in tank and in pump sales based on product temperature-expansion coefficient.

- Automatic detection of product deliveries in tank.

- Automatic detection of equipment alerts, errors and problems.

- Automatic data upload to remote server: uploading pumps sales, tanks measurements, in-tank deliveries, alerts and GPS records, real-time status of connected equipment to a remote server for reporting and analysis.

- Constant communication with remote server: communication is done using WebSockets protocol (according to RFC 6455 specification), allowing the remote server to get and set configuration, online monitor activity of pumps and tanks, generate reports and others.

- Conversion between pumps protocols: in case if POS system already knows communication protocols of dispensers - then it can use PTS-2 controller for its conversion to any other pump protocols.

- Conversion between ATG consoles protocols: in case if POS system already knows communication protocols of ATG consoles - then it can use PTS-2 controller for its conversion to any other ATG console or probe protocols.

- Real-time control over fuel dispensers and ATG systems. PTS-2 controller provides a hardware solution for stable and reliable operation of forecourt equipment.

- Possibility to provide control over same fuel dispensers from several POS systems: several control systems can connect to single PTS-2 controllers using Ethernet interface.

- Installation on existing petrol stations without any integration with POS systems: PTS-2 controller can be installed between existing POS systems and dispensers and ATG systems and provide monitoring, control and reporting.

- Wireless communication to forecourt equipment using the WFC wireless forecourt communicator.

- Rich set of interface converters for connection to fuel dispensers: PTS-2 controller can connect to dispensers with almost all types of electrical interfaces.

- Built-in web-server for configuration, monitoring, control, reporting, self-diagnostics and firmware update.

- Logging of operation: in order to remove problematic situations of PTS-2 controller communication with any forecourt equipment logging of communication exchange without interrupting PTS-2 controller operation is available, which allows quick search and elimination of any found problems.

- Self-diagnostics of operation: easy and quick built-in diagnostics of PTS-2 controller operation: CPU, memory, Ethernet, RS-232 and RS-485 interfaces, DIP-switches, SD flash disk.

- Constant software updates: PTS-2 controller firmware is constantly being improved, new protocols are being added and latest updates are always available for download to all customers.

- Easy firmware updating: all new firmware updates are available for download to all existing customers. Firmware update process takes about 1 minute.

- Support by developers for developers: support for all customers on any standing issues.

- Credit-card size: suits to any dimensions for installation inside master systems.

- Support more than 145 brands of fuel dispensers and register meters from various manufacturers: 2A, ACTRONIC, ADAST (ADAMOV SYSTEMS), AG WALKER, AGIRA, ANGI International, ARIEL, ASPRO, ASSYTECH, ASTRON, AZT, BAILONG, BARANSAY, BATCHEN, BENNETT, BLUE SKY, CENSTAR, CFT Clean Fuel, CHANGLONG, COMPAC, COPTRON, CORITEC, DATIAN MACHINES, DEM G. SPYRIDES, DEVELCO, DIGITAL FLOW, DINT, DONG HWA PRIME, DURULSAN, EAGLESTAR, ECOTEC, EHAD, EKOSIS, EMGAZ DRAGON, EPCO, ESIWELMA, EUROPUMP, FALCON LPG, FLOW, FORNOVO GAS, FUELQUIP, FUELSIS, FUREN HIGHTECH, GALILEO, GASLIN, GERKON, GESPASA, GILBARCO, GREENFIELD, HAKO, HITACHI, HONG YANG, IFSF (dispensers), IMW, INTERMECH, IPT, JAPAN ENERJUMP, JAPAN TECH, KAISAI, KALVACHA, KIEVNIIGAZ, KOREA ENE, KPG-2, KRAUS, KRIPFLOW, KWANGSHIN, LAFON, LANFENG, LAOXU, LIQUID CONTROLS, LG ENE, LOGITRON, MAIDE, MASER, MEKSAN / WAYNE SU86, MEKSER, MEPSAN, MIDCO, MIDCOM, MITHRA FUELING, MM PETRO (ZAP), MOTOGAZ, MOUNTAIN CHINA, MRT, MS GAS, NARA, NUOVA MIGAS, NUOVO PIGNONE, ONSUN, ORCA, PEC (GALLAGHER FUEL SYSTEMS), PECO, PEGASUS, PETPOSAN, PETROEQUIP, PETROMECCANICA, PETROTEC, PROWALCO, PUMP CONTROL, PUMPTRONICS, REAL-TECH, RIX, S.A.M.P.I. TEX, SAFE, SALZKOTTEN, SANKI, SATAM EQUALIS S, SAVEL, SEA BIRD, SHELF, SCHEIDT & BACHMANN, SHIBATA, SLAVUTICH, SOMO PETRO, STABILIZING, STAR, TATSUNO (JAPAN), TATSUNO EUROPE (FORMER BENC), TATTAN, TAURUS, TEKSER, TIGER, TOKHEIM, TOKHEIM INDIA, TOKICO, TOMINAGA, TOPAZ, TOTAL CONTROL SYSTEMS TCS 3000, TRANSPONDER, TRUE TECH, UCAR ELEKTRIC, UNICON-TIT, VANZETTI, WAYNE DRESSER, WAYNE PIGNONE, WELLDONE MACHINES, WERTCO COMPANY TEC, WINTEC ENERGY, YENEN, ZCHENG GENUINE MACHINES, ZHONGSHENG and others.

- Support more than 50 types of automatic tank gauge (ATG) systems of various manufactures: ACCU, ALISONIC, ASSYTECH, BLUESKY, CENSTAR, DUT-E, EAGLESTAR, EBW, EMERSON ROSEMOUNT, ENRAF, ESCORT FD, FAFNIR, FRANKLIN FUELING, GAMICOS, GILBARCO VEEDER ROOT, HECTRONIC, HOLYKELL, HONG YANG, HUMANENTEC, IFSF (ATG systems), INCON, KANGYU, KUNLUN, LABKO, LIGO, MECHATRONICS, MEPSAN UNIMEP, MTS ATG SENSORS, ND, NORTH FALCON, O.L.E., OKET, OMNICOMM, OMNTEC, OPW, PHOENIX, QINGDAO GUIHE, RCS EPSILON, RIKA, SENSOR, SINOTECH, SKE LEVEL GAUGE, START ITALIANA, STRUNA, TECHNOTON, TENET, UNIPROBE, VEGA, VEPAMON, WINDBELL, XT SENSORS, ZCHENG GENUINE MACHINES and others.

- Support different types of price signs of various manufactures: BEVER INNOVATIONS, GILBARCO, NOVYC, PWM, RGB TECHNOLOGIES, TOP SCREENS, U-GREAT LED, UMLED and others.

- Support different types of RFID readers and automatic vehicles identification systems of various manufactures: VRD-485, HECTRONIC AVI, HID AVI, LOOPTAG AVI, MINGTE AVI and others.

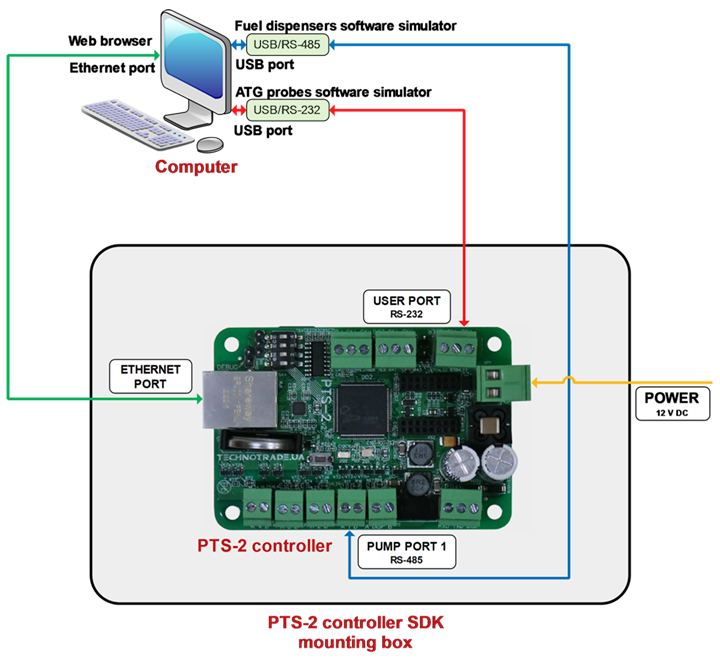

PTS-2 controller SDK (Software Development Kit) #

PTS-2 controller SDK (Software Development Kit) is intended for developers of POS management software for petrol stations that want to control fuel dispensers and ATG systems from their software.

PTS-2 controller SDK includes:

Hardware:

- PTS-2 controller over fuel dispensers and ATG systems for petrol stations: 1 pc

- Interface converter RS-232/USB with cable: 1 pc

- Interface converter RS-485/USB with cable: 1 pc

- Cabling

Software:

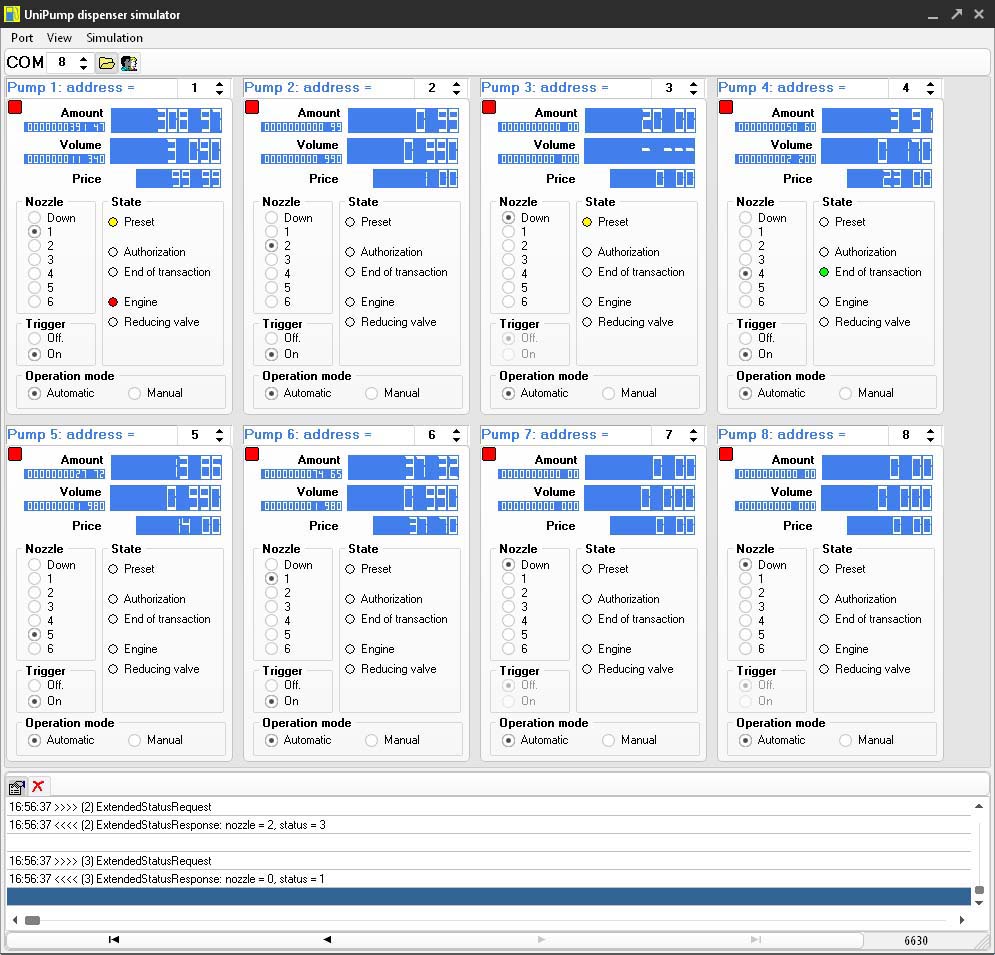

- Software simulators of prevalent fuel dispensers

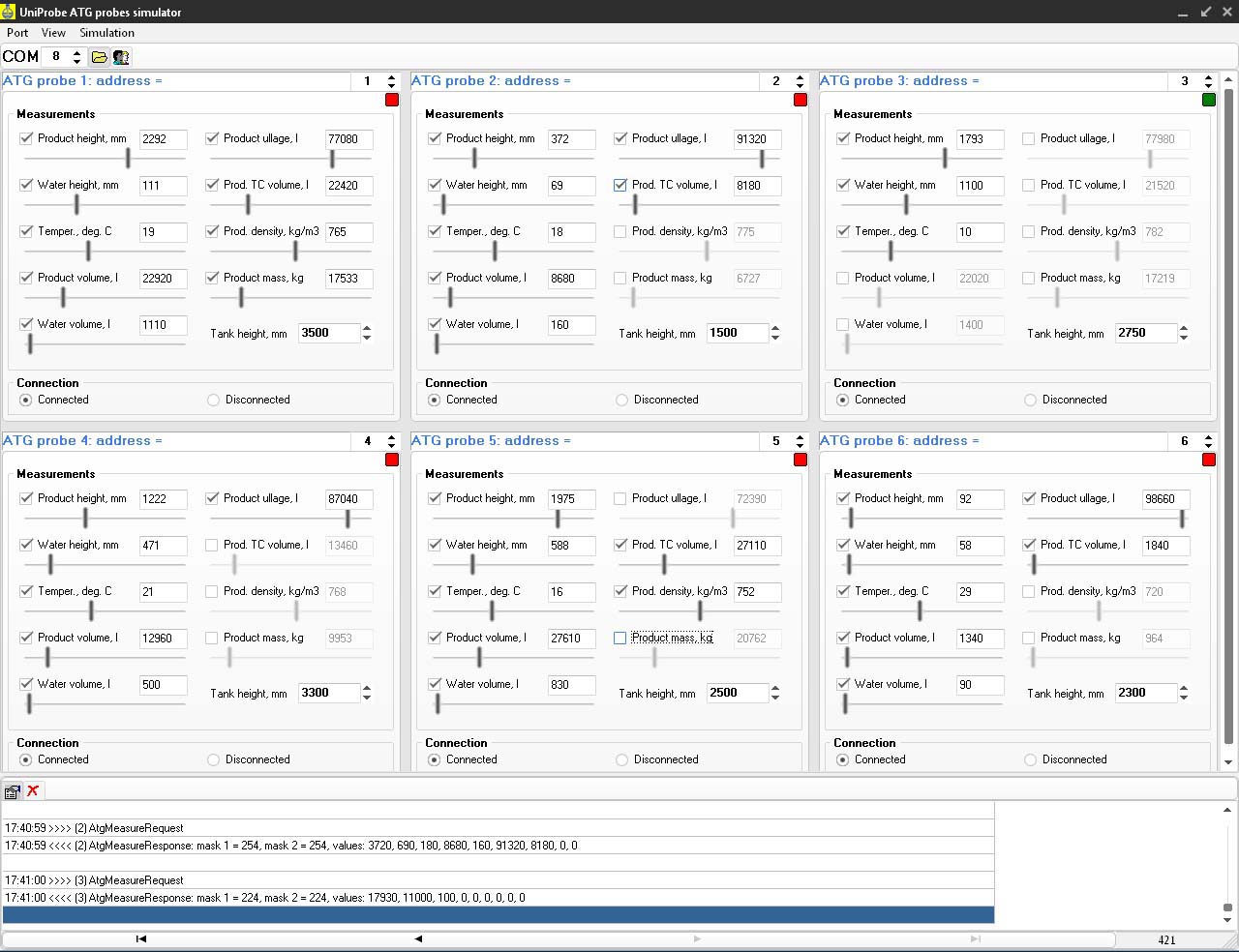

- Software simulators of ATG systems (probes)

- API for developers (with open-source applications in C++, C#, Java from Android, JavaScript languages)

PTS-2 controller SDK is required and designed for software developers for:

- Study operation with the PTS-2 controller.

- Implement the PTS-2 controller into own developed POS system or software application for control over fuel dispensers and ATG level measurement systems for petrol stations.

- Debug own software application to correctly provide control over various popular fuel dispensers locally (on the workplace) without a necessity to go to the petrol station and connect to real fuel dispensers and ATG probes using supplied with PTS-2 controller SDK fuel dispensers and ATG probes software simulators.

Software simulators

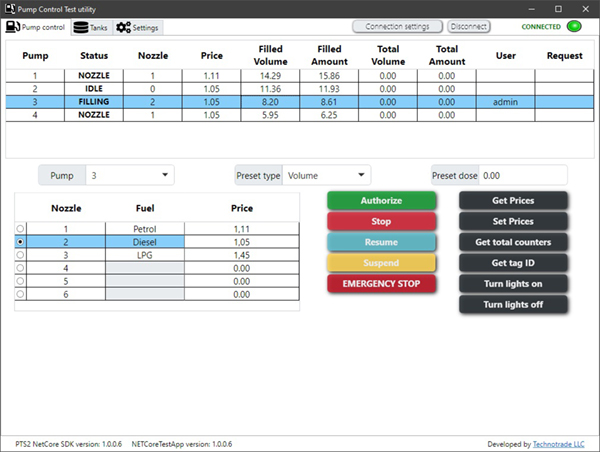

.NET Core API and open-source application

PTS-2 controller SDK includes .NET Core API library and an open-source application compatible with various operating systems (Windows, Linux, MacOS) with different processor architectures.

Android API and application

In order to help developers of the payment applications and management systems to easier and faster implement the PTS-2 controller in their applications our team developed an API library and open source application for Android platform. You can use this code in your own applications for communication with the PTS-2 forecourt controller. It is running the latest version of Android platform and we are providing constant updates and improvements for it.

Nowadays totally we provide API and open source applications for the PTS-2 controller in the following programming languages:

- C# (.NET Core)

- C++

- Java for Android

- JavaScript

Order information #

Ask YOUR questions about

"PTS-2 forecourt controller"

Other products of section:

|

U2L converter

U2L converter converts from IFSF protocol with LON interface to Tokheim UDC protocol with RS-485/RS-232 interface and backwards, it is intended for communication of POS systems and controller with dispensers, which use LON interface and IFSF protocol, through interfaces: RS-232, RS-485, RS-422.

|

L2D converter

L2D converter converts from IFSF protocol with LON interface to any dispenser, which supports DART protocol with RS-485 interface and backwards. It allows POS systems and forecourt controllers, which use only IFSF-LON to communicate with any dispenser using DART communication protocol.