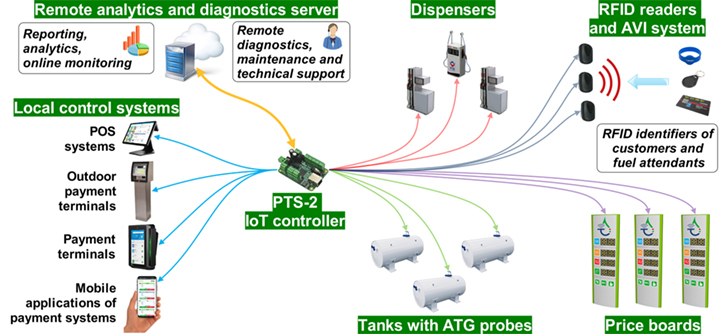

Data gathering from remote gas stations, petroleum depots and fuel delivery trucks

Being installed on petrol stations without static IP-addresses or in the mobile fuel delivery trucks sometimes there is a task to communicate to a remote server to gather information for reporting, to receive some updates in configuration or even for remote control from a server. For such tasks the PTS-2 forecourt controller can itself establish connection to a remote server by its IP-address.

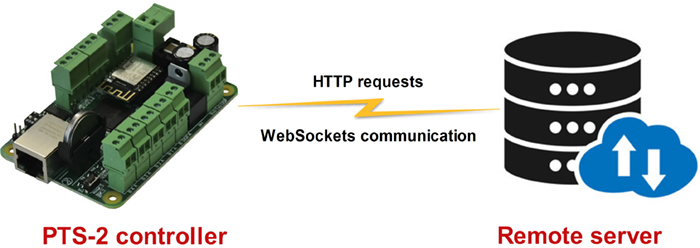

PTS-2 controller is able to constantly communicate with remote server without a need to have a static IP-address for upload of data to the remote server online for reporting and analysis. PTS-2 controller can connect to a remote server itself and upload all the data in JSON format, which is convenient for processing, so any third-party servers can easily implement support of PTS-2 controller to work with its data.

Also, PTS-2 controller can establish constant connection to a remote server using the WebSockets protocol (according to RFC 6455) with a purpose to allow the server to execute any requests it needs like setting/getting configuration, provision of control over pumps and tanks, getting reports, etc. This application is important when a remote server should completely control PTS-2 controller.

In both cases the PTS-2 controller connects to a remote server as a client, so there is no need to have any static IP-address on the place of PTS-2 controller installation.

The PTS-2 controller allows to upload the following information to a remote server:

- Information on each performed pump transaction:

- pump sale start date and time

- pump sale end date and time

- pump number

- nozzle number

- fuel grade ID

- transaction number

- pump price

- dispensed volume

- dispensed temperature-compensated volume (volume converted to 15 degrees Celsius)

- dispensed money amount

- value of volume counter in pump on the transaction end

- value of money amount totalizer counter in pump on the transaction end

- value of customer or fuel attendant tag applied for the transaction (the fuel attendant ID card to authorize the pump or the customer's discount/loyalty card)

- ID of a management system authorizing a pump (local POS system or OPT)

Having this data the remote server is able to:

- generate reports with all details on each pump sales done

- calculate the flow speed of each pump nozzle

- check if there were stealings of fuel done through authorized sales without the controller control (by the pump totalizers counters, which are non-erasable and non-resettable and are incremented regardless the transaction is done in manual mode or automatically, so in case if the totalizers counters were incremented more than a sale done - then someone was doing a filling when a pump is in manual mode, which might be a theft)

- decide which pump is more attractive and more productive

- others

- Information on each registered tank measurement (the PTS-2 controller uploads the tank measurements data to a remote server each time it detects a change in the product height):

- date and time of measurement

- tank number

- probe error

- alarms present (products height low or high, water height high)

- product height value

- water height value

- product temperature value

- product volume value

- water volume value

- tank ullage volume value

- product temperature-compensated volume value

- product density value

- product mass value

Having this data the remote server is able to:

- have online data for each tank

- have statistics for each tank usage with a possibility to make forecasting for future needs

- if combined with data on pumps sales from the tank the remote server is able to generate reports on reconciliation meaning to see how much fuel has to be stored in the tank on some moment and how much is actually stored there and thus to understand if there is a possible leakage or thefts from the tank.

- others

- Information on each registered in-tank delivery (the PTS-2 controller itself monitors tanks for in-tank deliveries, saves them to database and uploads to a server):

- date and time of in-tank delivery start

- date and time of in-tank delivery end

- tank number

- product height value on in-tank delivery start

- product height value on in-tank delivery end

- water height value on in-tank delivery start

- water height value on in-tank delivery end

- product temperature value on in-tank delivery start

- product temperature value on in-tank delivery end

- product volume value on in-tank delivery start

- product volume value on in-tank delivery end

- product temperature-compensated volume value on in-tank delivery start

- product temperature-compensated volume value on in-tank delivery end

- product density value on in-tank delivery start

- product density value on in-tank delivery end

- product mass value on in-tank delivery start

- product mass value on in-tank delivery end

Having this data the remote server is able to understand how much fuel was received in each tank.

- Found errors and alarms:

- detected pumps offline status

- detected pumps errors

- detected probes offline status

- detected probes errors

- detected probes alerts (critical high product height, high product height, low product height, critical low product height, high water height)

- detected tanks leakages

- detected tanks probes floats stuck

- detected price-boards offline status

- detected price-boards errors

- detected readers offline status

- detected readers errors

- operation time of the controller

- detected absence of power supply

- low battery voltage

- high CPU temperature

- others

Having this data the remote server can instantly alarm technical personnel about the found problems to quickly solve them and thus keep the petrol stations work stable and safe.

- GPS tracking records (in case if the PTS-2 controller is installed inside a fuel delivery truck):

- date and time of GPS record

- fuel track latitude value with North/South indicator

- fuel track longitude value with East/West indicator

- fuel track speed over ground

- fuel track course over ground

Having this data the remote server can display location of the fuel track on the map with indication what is its speed and height over ground. Also, it can know in which places the fuel delivery truck made fillings and also product level changes in tank were detected (as a mean to define possible stealings of fuel along the fuel delivery truck movement).

- Online realtime status of each pump (meter), tank probe, GPS receiver, alerts and the PTS-2 controller: having this information the remote server is able to know everything happening realtime on the sight. Data is sent each second or faster, the server software can use its own algorithms for calculation of various indicators as it was connected to the forecourt equipment itself locally.

- PTS-2 controller configuration: the remote server is able to remotely receive configuration from the PTS-2 controller and also to update the configuration in the PTS-2 controller. As an example the remote server having sent the fuel grades prices update request to the PTS-2 controllers will automatically update of prices on the pumps and in the price boards on the whole network of petrol stations.