AlphaSonic ultrasonic level sensors

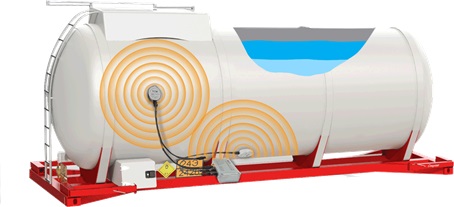

AlphaSonic sensors are used for continuous non-invasive, digital, automatic measurement of LPG level and other liquids such as water, chemicals. AlphaSonic measures the level mainly in aboveground stationary cylindrical metal tanks from 10 cm up to 4 meters depending of the liquid density. Sensor has measurement error from 5% up to 1 mm depending on the model. Can be installed in the 0 explosive zone.

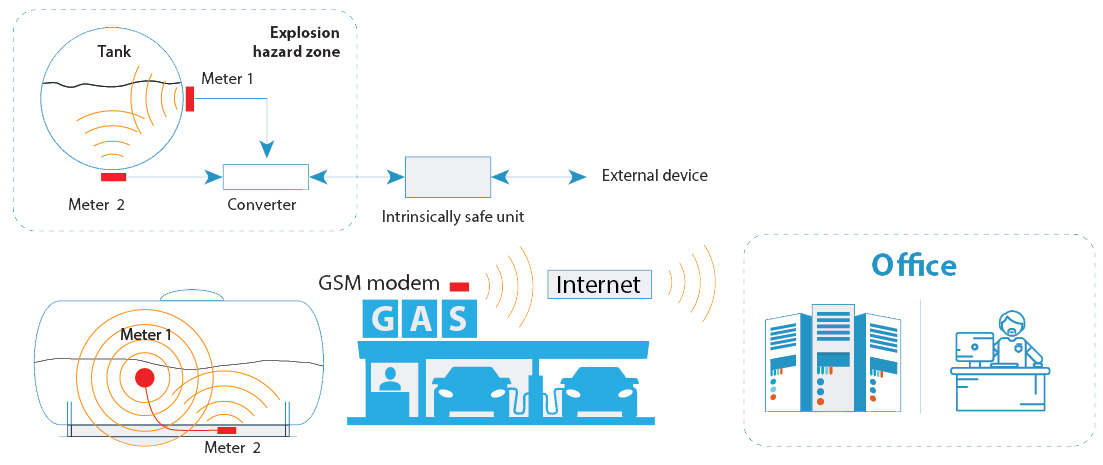

AlphaSonic sensor is a device that consists of one or two ultrasonic emitters/meters connected to a signal converter. Converter is connected to intrinsically safe unit. The barrier is not included in the installation set and supplied as a separate, independent product. AlphaSonic has RS-232 and RS-485 outputs and can be easily connected to GPS tracker, PC, notebook, smartphone or digital indicator.

Downloads

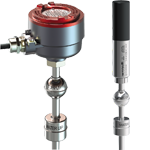

AlphaSonic-30 level sensor type #

- Maximum error: ±1 mm

- Continuous automatic non-contact measurement of fuel and LPG levels

- Multi-layered security

- Two built-in temperature sensors

- Communication interfaces: RS-485, RS-232

- Non drill installation

- Ultrasonic meters and converter have II2GExibIIВT4Gb explosive marking

- Intrinsically safe unit has II(1)G[ExiaGb]IIB explosive marking

Side ultrasonic reference meter measures properties of the medium (speed of sound). Bottom ultrasonic meter measures level of the liquid. This data is used to increase accuracy of measurements.

Equipped with two separate temperature sensors that measure temperature of the liquid to increase the overall measurement accuracy.

|

Bottom installation of ultrasonic meter + side installation of the second ultrasonic meter. A number of temperature sensors depending on the tank size. |

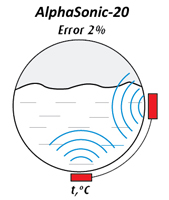

AlphaSonic-20 level sensor type #

- Maximum error: 2%

- Continuous automatic non-contact measurement of fuel and LPG levels

- Multi-layered security

- One built-in temperature sensor

- Communication interfaces: RS-485, RS-232

- Non drill installation

- Ultrasonic meters and converter have II2GExibIIВT4Gb explosive marking

- Intrinsically safe unit has II(1)G[ExiaGb]IIB explosive marking

Side ultrasonic reference meter measures properties of the medium (speed of sound). Bottom ultrasonic meter measures level of the liquid. This data is used to increase accuracy of measurements.

|

Bottom installation of ultrasonic meter with inbuilt temperature sensor + side installation of the second ultrasonic. |

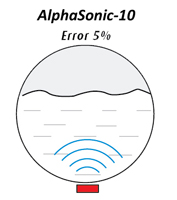

AlphaSonic-10 level sensor type #

- Maximum error: 5%

- Continuous automatic non-contact measurement of fuel and LPG levels

- Multi-layered security

- One built-in temperature sensor

- Communication interfaces: RS-485, RS-232

- Non drill installation

- Ultrasonic meters and converter have II2GExibIIВT4Gb explosive marking

- Intrinsically safe unit has II(1)G[ExiaGb]IIB explosive marking

- Simple, cost-effective

AlphaSonic-10 model consists of the bottom ultrasonic meter that measures level of the liquid.

|

Bottom installation of the ultrasonic meter. |

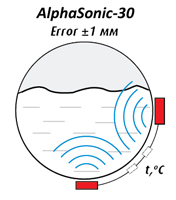

Operation principle #

AlphaSonic sensor emits ultrasonic waves into the tank and receives the reflected signal, which is transmitted to the converter.

Lower ultrasonic sensor measures the distance to the separation of liquid. Side ultrasonic sensor is used to measure properties of the liquid (speed of sound). It corrects the readings of the lower sensor in order to increase the accuracy of measurements.

In the AlphaSonic-30 model, a number of side mounted temperature sensors are connected to the ultrasonic sensor. They measure temperature of the liquid, which is also intended to increase the accuracy of measurements.

Converter calculates the level according to the results of processing information from the meters. It transmits data through the external galvanic isolation in the intrinsically safe unit. The unit, in its turn, is connected to external device for further processing via the RS-485 or RS-232 interface.

Specification #

AlphaSonic sensor characteristics

| Resolution, mm | 0,1 |

|---|---|

| Measurement error: ULB-10 ULB-20 ULB-30 |

5% 2% ±1 mm, OIML R-85 |

| Temperature range, °С | – 40 … + 75 |

| IP protection rateмм | IP67 |

| Explosion-proof marking | II 2G Ex ib IIВ T4 Gb |

Intrinsically safe unit characteristics

| Voltage, V | +9 …+36 |

|---|---|

| Temperature range, °С | – 40…+ 75 |

| IP protection rate | IP67 |

| Current consumption, max mA | 250 |

| Explosion-proof marking | II (1) G [Ex ia Ga] IIB |

| Communications interfaces | RS-485/RS-232 |

| IP protection rate, mm | RS-485/RS-232 |

| Explosion-proof marking | II 2G Ex ib IIВ T4 Gb |

General installation scheme #