Fuel measurement system "STRUNA" for petrol stations and storage depots

Measurement in units of volume and weight

Measurement system “Struna” – is an automation of measurement of parameters of light petroleum products and LPG at reception, storage and operational control of reservoir park of petrol stations and tank farms.

Systems are intended for measurement of level, temperature, density, pressure, calculation of volume and mass of light petroleum products and light petroleum gas (LPG) in single-wall and double-wall reservoirs, notifying about presence of produced water, levels of fire and environmental safety, automation of the process of measurement of petroleum products at petrol stations and storage depots. Systems can be applied in food and chemical industries.

Measurement systems “Struna” are certified measurement device in State register of measurement of Ukraine and Russian Federation, have explosion proof “intrinsically safe electric circuit of level ia” and comply with the requirements of standart series GOST R 51330.0-99, GOST R 51330.10-99, as well as IEC 60079-0-98, IEC 60079-11-99.

|

|

|

|

Measurement systems “Struna” provides:

- Precise remote measurement of level, density, temperature, pressure and mass of fuel and LPG in reservoirs (as well as benzines, diesel, oils, spirits, kerosenes, CNG, condenced gas, solvents).

- Calculation of volume of petroleum products in reservoirs in accordance with calibration charts of reservoirs.

- Calculation of mass of petroleum products with limits of allowed relative error ±0,65% (registered measurement method).

- Ability to automate and provide detailed record of movement of petroleum products and LPG on one or several petrol stations (or storage depots) during simultaneous operation of dispensing systems.

- Automatic control of impermeability of single-wall and double-wall (with liquid filler) reservoirs with light and sound notification.

- Gas pressure control in reservoirs with LPG or in interstitial space.

- Control over presence of produced water in reservoirs.

- Prevention of overflow of fuel during filling the reservoirs by giving control signals to switch off the pumps, light and sound notifications.

- Automatic calibration of reservoirs using special software.

- Control over dangerous concentrations of flammable fumes by switching on notifying and regulating mechanisms.

- Self diagnostics of functioning and metrological characteristics of the system in all modes of operation, including control over dynamics of level during reception of petroleum products. In case of malfunction it provides an ability to turn off pumps or close electromagnetic valves while notifying the user.

- Indication of measurement results and calculation of parameters on autonomous indicator, information output into the system or user program through a standart interface RS-232C, RS-485, USB.

- Metrological checking without dismantling of PPC with a help of internal means.

- Significant reduction of downtime of petrol stations at changing the working shifts.

Technical characteristics of the system:

| Range of level measurements (without density meter), mm | from 120 to 4000 |

| Range of level measurements (with “surface” density meter), mm | from 200 to 4000 |

| Range of level measurements (with “submersible” density meter), mm | from 120 to 18000 |

| Range of level measurement (for calibration of tanks), mm | from 0 to 4000 or from 0 to 9000 |

| Margins of allowed absolute error in a range up to 4 meters, mm | ±1,0 |

| Margins of allowed absolute error in a range more than to 4 meters, mm | ±2,0 |

| Resolution, mm | ±0,1 |

| Exploitation temperature range of PPC, °С | from -40 to +55 |

| Limits of allowed absolute error of temperature measurement, centigrade degrees | ±0,5 |

| Ranges of density measurement, kg/m3: | |

| - 1 range (LPG) | from 499 to 599 |

| - 2 range (petrol with 80 octane number) | from 690 to 760 |

| - 3 range (petrol with octane numbers 92, 95, 98) | from 715 to 785 |

| - 4 range (diesel fuel) | from 810 to 880 |

| Limits of allowed absolute error of density measurement (with “surface” density meter), kg/m3 | ±1,5 |

| Limits of allowed absolute error of density measurement (with “submersible” density meter), kg/m3 | ±1,0 |

| Limits of allowed relative error of measurement: | |

| - Mass of petroleum product up to 120 tons, % max | ±0,65 (±0,3 typical) |

| - Mass of petroleum product over 120 tons, % max | ±0,5 |

| Signalling at presence of produced water at level (for fuel stations), mm | 25 |

| Range of measurement of produced water level (for petroleum storage depots), mm | from 80 to 300 |

| Limits of allowed absolute error of water level measurement (for petroleum storage depots), mm | ±1,0 |

| Range of overpressure measurement, MPa | from 0 to 1,6 |

| Limits of allowed reduced error of pressure measurement, % | ±1,0 |

| Quantity of controlled reservoirs (by 1 central unit) | up to 16 |

| Cable length from each reservoir to the operators' room, not more, m | 1200 |

| Parameters of control channels in a Control Unit: | |

| - power circuits (optosimistor) | ~220V; from 0,1 to 0,5A |

| - power circuits (dry contact) | ~220V; from 0,01 to 0,1A |

| - low power relay circuits (dry contact) | =27 V ; from 0,1 to 0,5A |

| System feed | 220V +10 -15 %; 50 Hz; 0,6А |

Structure of measurement systems “Struna”:

Central part:

- computing block (CB), that has explosion proof degree of ExiaIIB, intended for collection, primary convertion and processing of data on parameters of reservoirs (up to 16) and communication with external systems, computer, networks;

- specialized power supply unit (PU), that has explosion proof degree of ExiaIIB;

- blocks of clamp connections (BC), intended for connection of cables from primary parameters convertors (PPC).

- Indication block (IB), desktop case installed inside a premise, intended for indication of parameters of petroleum products in reservoirs. Provides feedback on the state of the system and allows input of parameters and selection of operation mode. Dimesions: 190 x 135 x 52 mm;

- Interblock cablings, interface convertors and exploitation documentation (ED).

Peripheral part:

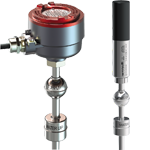

- Primary parameters convertor (PPC) with sensors of level, temperature, density, pressure and produced water (depending on execution method). Made in explosion proof case, has a degree of explosion proof ExiaIIB and is installed in reservoirs.

- Control unit (CU), which is installed inside the premise and is intended for programmable switching on and off siren (light and sound signals) as well as execution mechanisms (valves, pumps). Dimensions of a case: 305 x 178 x 75 mm.

- Interblock cablings, interface convertors and exploitation documentation (ED).

Peripheral part:

- Control unit (CU), which is installed inside the premise and is intended for programmable switching on and off siren (light and sound signals) as well as execution mechanisms (valves, pumps). Dimensions of a case: 305 x 178 x 75 mm.